Ask professionals of any trade whether it’s better to repair something or prevent it from being damaged in the first place, and the answer will be unanimous. Prevention is a central tenet of proper maintenance, saving money, labor, and frustration. That’s even more true when maintaining the critical infrastructure that millions of Americans rely on every day.

Much of our nation’s road network is concrete—including more than 259,000 concrete bridges listed in the Federal Highway Administration’s InfoBridge database. Replacing deteriorated concrete is expensive and time-consuming, so preserving the concrete in our roads and bridges is crucial to keep America moving. However, conventional concrete sealers don’t offer the long-term protection needed and can even accelerate damage in some circumstances.

PoreShield™ is different. Unlike most sealers that only form a coating over the surface of concrete, PoreShield soaks deep into the pores. While surface sealers often wear away by abrasion or crack from weathering within two to five years, PoreShield stays in the pore network, blocking damage from fluid and ions for more than 10 years.

But longevity is only part of PoreShield’s appeal. Read on to see how PoreShield saves time and money while eliminating many of the negatives associated with conventional concrete sealers.

MAXIMIZING ROI

In June 2020, the Wabash County Highway Department in Indiana applied PoreShield concrete durability enhancer to the surfaces of six bridges. Based on typical application timelines, the department had expected these applications to take at least two days. However, the application process was completed faster than expected, with four of the bridges treated before noon the first day.

While PoreShield is used on PCC joints, bridges, and many other concrete surfaces, Wabash County focused on its bridges first because of their vulnerability. Bridges typically use denser concrete than roads and contain steel beams susceptible to moisture, so damage that occurs on bridges is greater and more expensive to fix than on paved roads.

Not only was the application process quick, but it was safer for the applicators than if they had used a conventional sealer. PoreShield is made from soybeans, meaning it is nontoxic and low VOC, with no PPE or special equipment required for application. Cleanup is quick and easy since there is no hazardous material involved. Because it is uniquely friendly to the environment, it can be applied over a body of water without contamination concerns, which is ideal for bridge applications.

“The biggest surprise was probably the environmental friendliness of [PoreShield],” says Cole Wyatt, the Wabash County highway superintendent who oversaw the project. “You don’t have to worry about inhaling noxious chemicals all day; you’re not dealing with burns or anything of that nature. The fact that we can come out here, if we get a little on us and we catch some vapors, it’s not harmful. That’s a huge benefit.”

After his positive experience with PoreShield, Wyatt decided to establish a protocol for treating a handful of Wabash County’s bridges each year. His goal was to have them all treated with PoreShield within four or five years. This practice will add years to the life of critical infrastructure, for less than a tenth of a percent of the cost to replace the structure. One 25,000-square-foot bridge can be treated in one hour using approximately 140 gallons of PoreShield, with that protection lasting for more than 10 years.

“It’s going to be a long-term positive for the budget,” Wyatt says. “It will make the infrastructure last longer and it justifies the cost. When we apply for grants, the investment in this product shows we are maintaining our current assets, so we will see more than a return on investment through the grant process.”

PASSING THE TEST

Many other local and state agencies have adopted PoreShield into their preventive maintenance programs, including the state departments of transportation for Indiana, Wisconsin, Iowa, and Nebraska. The Wisconsin DOT even funded a comprehensive independent study that put PoreShield up against conventional sealers to determine the best method for reducing chloride ion diffusion—a common type of concrete damage. Released in March 2020, the study found that PoreShield was more than twice as effective as penetrating sealers at stopping chloride ion diffusion more than a half-inch below the surface.

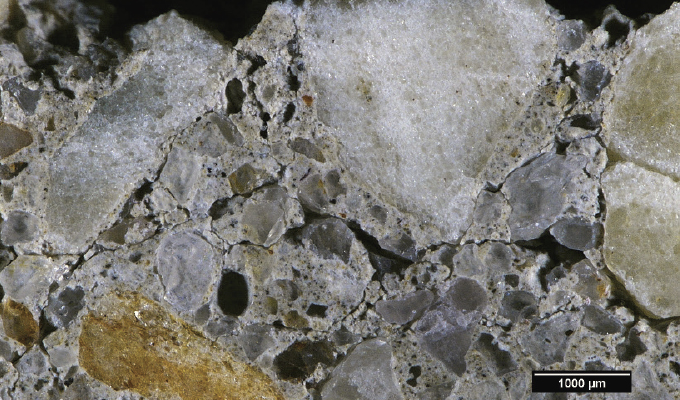

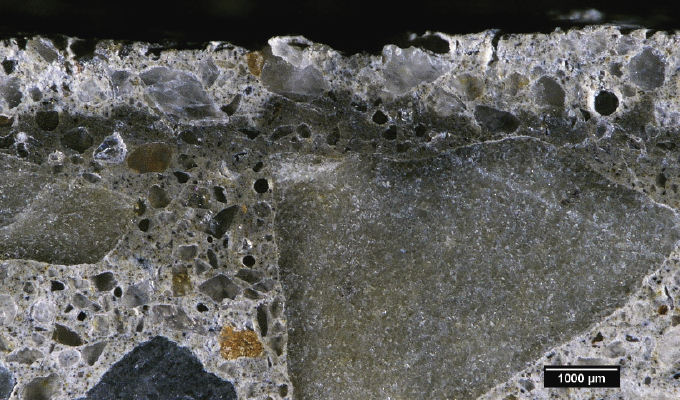

Another study performed at Drexel University in Philadelphia put PoreShield through a rigorous test to measure salt scaling prevention. Concrete samples were submerged in salt water, then frozen and thawed every day for 10 weeks to simulate the effect of deicing salts used on roads during the winter. By the end of the test, the untreated samples showed scaling, loosened aggregate below the surface and 250mg of mass lost. The samples treated with PoreShield were intact and had lost less than 10mg of mass.

CLOSING THOUGHT

In both the lab and the real world, PoreShield has proven effective at preventing concrete deterioration without endangering workers, budgets, or schedules. And the uses for PoreShield continue to grow, from newly cured concrete to decades-old structures, from hog barns to salt storage buildings. Make prevention a priority for your concrete with PoreShield.

For More Information:

For more about Crafco’s PoreShield™, visit poreshield.com.

Modern Contractor Solutions, December 2023

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.