Even from Link’s very first days—in the small (often smoke-filled) garage that would serve as the testing ground for the original Cabmate® cab suspension—the guiding principle was to keep the focus on the customer. Link’s founder, Bill Nibbelink, was a truck driver-turned innovator who wanted a solution to the jarring ride that he had to endure on a daily basis. From that beginning 35 years ago, Link has remained committed to developing product and process innovations that save time, money, or improve driver well-being.

LIFT AXLES: SIMPLICITY BY DESIGN

That focus has continued in Link’s product development through the years. Nowhere is this more evident than in Link’s line of self-steer and non-steer lift axles. Link’s patented interchangeable ride height brackets and integrated air kit can allow installers to save 2-3 hours of installation time. The bracket kits also reduce inventory requirements—enabling shops to stock brackets instead of axles. With standard 5-Day lead times and award-winning customer service, drivers and owners experience limited down time, helping to increase profitability.

“The mounting system is second to none,” notes owner-operator, James Todd. “In the off-season, I can remove my Link pusher in less than 25 minutes by myself, with no hoist. It’s a great design!”

Link extended that customer-first product commitment in 2012 when it acquired the capabilities of Raydan Manufacturing and formed Link Suspensions of Canada. Now, the Link family of companies provides a complete line of vocational suspensions, including twin steer and tandem drive offerings.

IDAHO TURNS TO LINK

The Idaho Transportation Department had a 2006 Mack® Granite™ outfitted with an Altec® digger/derrick body, which it could use to install and service traffic signs. A boom mounted behind the cab had an auger for drilling holes as well as a bucket for reaching signs. The chassis for this truck included an 18k front suspension and a 40k rubber block rear suspension. By late 2013, the truck had approximately 70,000 miles on it—and had been racking up countless driver complaints for over 18 months.

The Idaho Transportation Department contacted their regional Mack truck dealer, Northwest Equipment Sales, for help. Northwest Equipment made several attempts at resolving the ride issue: replacing rubber blocks in the suspension, removing leaf springs, changing tire pressure, and installing a progressive-rate overload bumper. Despite the mounting repair costs, these attempts only offered temporary relief before the ride would again become painful for the drivers.

Northwest Equipment made inquiries with the manufacturer of the existing rear suspension, asking if they could do anything. The manufacturer told Northwest Equipment that the problem was not with the suspension; a new chassis, valued at approximately $175,000, would be required.

In search of alternative options, Northwest Equipment contacted Link Manufacturing in August 2013. After a detailed examination, Link determined that the boom’s vibration was transferring from the rigid suspension and frame into the driver’s cab itself. That was the cause of the harsh ride.

The Idaho Transportation Department had a 2006 Mack® Granite™ outfitted with an Altec® digger/derrick body used to install and service traffic signs. The truck’s ride received several complaints over several months. Link provided the solution.

LINK’S SOLUTION

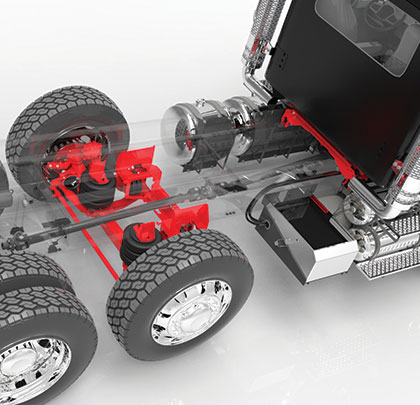

Link’s solution was the Air Link® Tandem Drive Suspension. Air Link combines two proven suspension technologies: a walking beam that links the front and rear axles together, providing a combination of load equalization with an air suspension, which delivers a softer ride than a mechanical suspension. This solution was viable because it could be retrofitted into the existing chassis, eliminating truck downtime. Overseeing the installation would be Dan English, a member of the original Air Link suspension development team. Northwest Equipment was in favor of the proposal and secured approval of the retrofit, which took place in October 2013.

Following the installation, the truck was test driven by the service manager and the crew boss from the Idaho Transportation Department. They were astonished at the quality of the ride, and affirmed that the result exceeded their expectations. The real test, however, was what the drivers would say after using the truck for a normal workload. Steve Spoor, maintenance service manager at the Idaho Transportation Department states, “Our drivers gushed over the drastically improved ride. Gone was the constant slap-in-the-back that had existed with the previous suspension.”

But driver health and attitude were not the only benefits. The Air Link suspension improved uptime for the truck and it eliminated the need to replace the entire truck chassis. Furthermore, Link’s support and sense of urgency in solving the problem left a lasting impression.

“Other suspension providers offered air suspensions or walking beam suspensions: only Link provided a solution that combined the two,” says Jerry Schafer, general manager of Northwest Equipment. “Link’s greatest value was that they determined the root cause of the problem and developed and supported the installation of the solution.”

Since that first Cabmate, Link’s pledge has been superior service and support; outstanding product quality; and consistent, on-time delivery to every customer. That pledge is reflected in Link’s tagline: “Your Trust … Our Passion!” ■

For More Information: Link Mfg. is a privately owned company that develops and manufactures of a variety of suspensions for commercial vehicles and equipment. For more information, visit www.linkmfg.com/products/air-link.

_________________________________________________________________________

Modern Contractor Solutions, July 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.