By Ankit A. Sehgal

If you are a contractor who has been tasked with a project that involves the installation of trench drains, there are certain factors to consider when deciding which types would be best for your project. Let’s look at the principal factors that help determine the right solution.

Flow Rate. The very reason behind installing a trench drain is the rate at which these can remove liquid from the site in question. This is known as the flow rate and one must go for a trench drain with the right one for our purposes. The depth of the trough, as well as the width of the slot, determine the flow rate. For instance, an inch-wide slot opening could help expel as much as 11 gallons of liquid per foot of slot.

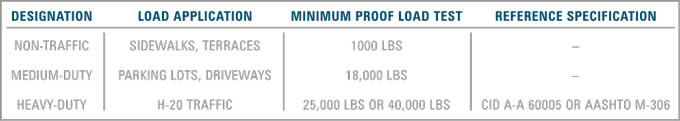

Load bearing capacity. The trench drain that you install including the grate should be able to handle the load that it is subject to, both in terms of the amount of liquid that needs to be expelled and the movement of people and equipment over it. Different sites witness varying quantities of load and it makes sense to install a drain with the correct load-bearing capacity.

Ability to resist chemicals and heat. The reason that trench drains need to be chemical resistant is that they need to be washed with cleaning chemicals from time to time and should not corrode on account of that. The liquids that trench drains have to deal with often flow out at high temperatures. Prime examples of this are food processing units and breweries. The material used to construct both the trench and the grate should therefore be able to withstand the temperature at which the liquid flows.

Longevity. Getting a trench drain installed is a long-term investment and a contractor must choose a reputed manufacturer or supplier. This will ensure that the trench drains will see long years of use without getting degraded in any manner.

Easy maintenance. Trench drains by their very nature need to be cleaned and generally maintained on a pretty regular basis. So, it makes sense for a contractor to install a trench drain that provides provision for cleaning, upkeep and maintenance. It is all very well to install a well-designed trench drain, but if it cannot be easily accessed for cleaning and maintenance, you would likely have a problem on your hands.

CHOOSE THE BEST

When it comes to choosing the best commercial and heavy-duty trench drains, it is important to remember that the idea is to optimally utilize one’s time, money, and resources. For instance, new age trench drain systems are longer and lightweight, yet structurally strong. Their modular design makes it possible to install them without having to resort to any form of heavy lifting or an excessive amount of equipment and manpower.

Prefabricated heavy duty trench drains are quite a popular option with contractors on account of their wide range and versatility of use. These are pre-sloped and come in varying widths: 2 inches, 4 inches, 6 inches, 8 inches, and to 48 inches. That apart, these are composed of a stable thermal set polymer body that is temperature resistant making them just right for the most stringent of environments. The frames themselves come in a variety of options-iron, stainless steel, galvanized steel, painted steel, bronze, aluminum, plastic, and fiberglass.

What is great about modern trench drains is that they can be very discreet and low profile despite their heavy-duty nature making them ideal for commercial projects that require that kind of an arrangement. Even though these are prefabricated trench drains these can handle flows as large as 35 cfs and have proved their mettle in manufacturing, power plants, seaports, water treatment plants, and so on.

FACTORS TO CONSIDER

- The commercial trench that a contractor chooses must be out of the top drawer for several reasons. An important one is compliance. The trench drains installed should conform to the necessary local regulations.

- Consider the design and materials, which should suit the site conditions. It is important to install trench drains that are hydraulically efficient making it possible for them to evacuate liquids in the most efficient way possible.

- The design of a heavy-duty trench drain is of prime importance. For example, if the load to be handled by it is extremely heavy, it would make a lot of sense to go for a durable stainless-steel drain that can manage it well. A slot drain that does not need a grate and can be directly embedded into a concrete floor might also be eminently suited for such purposes.

- The contractors should make it a point to only install trench drains that are supplied by an organization that provides an excellent backup in terms of the technical competence of its staff. They should be able to provide advice on matters of water management layouts, hydraulics, the choice of products, installation, and maintenance.

CLOSING THOUGHT

Trench drains might appear to be a pretty simple and straightforward technology used for the evacuation of liquids, but there is a lot of science behinds it. From the design and type of material to be used to the flow rate and load-bearing capacity of the trench drains in question, there are a lot of factors that go into the deciding which type of commercial or heavy-duty trench drain to install at a particular site. And, since trench drains are meant to last for a long time and play an important function in keeping a site dry and safe, due care must be taken in choosing the right one—one would do well to look at a trench drain solution rather than just a product.

about the author:

Ankit A. Sehgal is the president and head of engineering at Swiftdrain Inc., a global drainage and infrastructure products manufacturing company. He oversees all product design and development at the firm, including engineering, materials sourcing, and production. For more, visit swiftdrain.com.

Modern Contractor Solutions, July 2020

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.