new technology improves accuracy of familiar tool

For contractors frustrated by conventional stud finders that are inaccurate and unreliable, more advanced versions with six times the sensors are finally providing a solution. Combined with a wider, horizontal display of up to 7 inches, these more advanced stud finders reliably identify the full width of the stud.

The multiple sensors enable far greater accuracy when securely fastening objects to the center of studs, and as a result minimize wall damage. For some trades, it can also be critical to avoid studs when cutting into drywall for plumbing, electrical work, etc.

To examine the benefits of implementing a truly accurate stud finder for commercial/construction industry professionals, we discuss the advantages and benefits of this approach with David Dorrough, VP of technology at Franklin Sensors, an Idaho-based manufacturer of professional stud finders.

Q: Stud finders have been around a long time. What are the main drawbacks of the typical stud finders that contractors can find in the marketplace?

A: Contractors understand the value of having the right tool for the job. However, many are dissatisfied with traditional stud finders that require multiple steps, “error-out” frequently and provide inconsistent readings.

Although there is no shortage of stud finders in the market, traditional units have one or two sensors and may not delineate the location of studs clearly enough. Even higher priced options with LCD screens typically utilize the same one or two sensors as lower-end models and thus offer similar sensing technology.

Another problem with conventional electric stud finders is the multiple steps required for calibration and then locating the stud. A user is usually required to slide the unit from left to right until a stud is identified by a single LED light and an audible beeping sound.

The older style stud finder typically has a single indicator light that is supposed to show you when you hit the left and then the right side of the stud. But with only one indicator light, you are essentially left guessing.

Sometimes the stud finder starts beeping and flashing and you have to start all over again.

This can happen repeatedly, which can be tedious, frustrating, and unnecessarily slow down work that needs to be completed quickly to meet deadlines.

The problem is so prevalent that some contractors resort to alternative techniques like tapping into drywall with a small drill bit or finishing nail or rapping on the walls to physically locate each of the studs.

Q: So, what is different about more advanced stud finders in the market today?

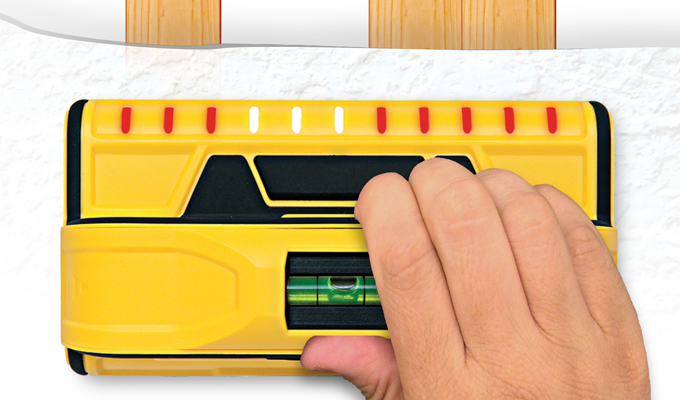

A: Today, more advanced units with a greater number of sensors can more accurately identify the location of the stud. Because these units are available in a horizontal configuration, the sensing and display area is much wider and can locate the edge and center of studs simultaneously.

Some of the most advanced stud finders utilize up to 13 sensors. One 7-inch, horizontally oriented device includes LEDs spaced across the entire width of the product that illuminate to show the full width of the stud—usually 3 lights for each standard 2” x 4”. Studs are shown, as well as any gap between them.

Conventional stud finders typically require six steps to take a stud reading: placing it on the wall; pressing a button; selecting correct mode; waiting for a calibration beep; sliding it to find the stud; and repeating this process from the opposite side. Instead, the advanced unit reduces this to one step: contractors just press the button and instantly begin detecting studs. No calibration is required.

Q: How can a contractor benefit from a more accurate stud finder?

A: When contractors know where the stud starts and where it stops, they know exactly where to drill to get the strongest support for the items they are mounting.

With a more precise definition of exactly where the stud is behind the wall, it allows contractors to be much more precise on interior finish work such as nailing base trim, installing fasteners or hanging cabinets etc. This helps prevent future call-backs and anything falling off that could cause injury or damage. The investment in a good stud finder helps mitigate any future problems of that sort.

Q: Are there any other benefits?

A: Advanced stud finders can save contractors a significant amount of time in finding studs, and this can translate into better, faster, more accurate bids.

For contractors, accurately knowing where the studs are—and are no—is critical for bidding and completing a job without serious complications. If a contractor is remodeling, he or she will often need an accurate picture of what is behind the wall without having to cut into it. A more accurate stud finder can tell you how much room there is to work with, if the studs are plumb or are running horizontally, etc. This can help contractors more accurately estimate the time it will take to complete a job.

So, advanced stud finders can help contractors provide a more accurate estimate that, in some cases, also reduces the cost for the customer. There is less guesswork as to what is going on behind the drywall, so the contractor does not have to charge for worst-case scenarios to cover potential extra work.

for more information:

For more, visit www.franklinsensors.com.

Modern Contractor Solutions, February 2020

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.