When a pothole appears on the streets of Edmond, Oklahoma, residents expect it to be filled within 24 hours. That doesn’t leave a lot of time for procurement or preparation, so the City of Edmond’s Street and Traffic Division needed a solution that installs easily, has a long shelf life, and is workable in any weather condition.

THE SOLUTION

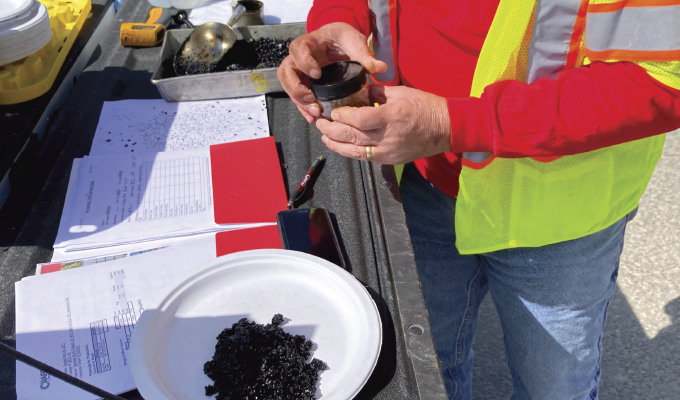

For the last 8-10 years, their strategic reserve has been stocked with Crafco HP ER Cold Patch™, which meets the city’s demands and provides a repair that lasts.

Herb Mason, assistant superintendent for field services with the City of Edmond, says all-weather workability was a top consideration for the city. HP ER Cold Patch is formulated for all-weather use and adheres well to cold and damp pavements.

“After we’ve had a weather event, we send out multiple pickups with this product in the back to get those small potholes before they become big ones,” Mason says. “The patch really stays, it sticks well, and it doesn’t pop out of the hole when people drive across it.”

Along with the performance in cold and wet conditions, Mason says the long shelf life of the HP ER Cold Patch has served his division well, allowing his team to keep plenty of ready-to-use asphalt cold patch available for whenever the need arises. Crafco’s product doesn’t harden in the bag or need to be kept warm, so it’s easy to stockpile large quantities for months without upkeep.

“By having material in the yard, if you’re going through some of it on a regular basis, you can have enough for an emergency repair on a weekend or whatever time it might come up,” he says.

Thanks to HP ER Cold Patch, Mason’s division can make one-time repairs that will last several years without extra maintenance. This ready-to-use, zero-VOC material is designed for potholes, utility cuts, wide cracks, and other deficiencies in both asphalt and concrete pavements, including everything from highways to bridge decks to walkways. It even works on sports courts. With no mixing, heating, or special equipment required, HP ER Cold Patch is designed to help agencies complete patch jobs as efficiently as possible. After application and tamping, the product gains its full strength with compaction from traffic.

FROM PLANT TO ROADWAY

Crafco’s cold patch solution offers benefits for end users and producers alike. To ensure an efficient and profitable process from the plant to the roadway, Crafco offers its HP ER Enhancer program to producers. HP ER Enhancer is an organic viscosity modifier designed to blend with asphalt to produce Crafco’s HP ER Binder for cold patch production. Crafco packages its HP ER Enhancer in premeasured totes that are ready for producers to add to paving-grade asphalt. Following the guidance provided by Crafco, producers are able to create an eco-friendly asphalt binder that’s safe to work with, cost-effective, and garners positive reviews from end users.

For Geneva Rock, a supplier based in Salt Lake City, Utah, the program has been profitable since the company made its first batch of HP ER Cold Patch material in September 2021. Asphalt salesman Cody Mills says prior to working with Crafco, previous attempts at making cold patch were too cumbersome, involving tedious reprocessing and drying steps.

“When Crafco developed its HP ER, we could have totes of the material on hand that we just plug right into our asphalt plant and then make it like regular asphalt, that streamlined the whole process and made it so easy to use,” Mills says. “Speaking with our asphalt plant operators, they were blown away by how easy the process was compared to what it used to be.”

Mills says one of the reasons Geneva Rock stepped away from cold patch production in the past came down to safety concerns and a lack of payoff for the risk involved with using flammable materials. With Crafco’s non-VOC product, plant workers have peace of mind knowing they can blend it in a hot plant without risk of flash.

Customer feedback has also been positive.

“Reviews of it have been great,” Mills says. “We’ve had guys say that they’re not going to buy anything else after they’ve used it.”

ECO-FRIENDLY BENEFITS

At APAC, a producer with locations across Kansas, Crafco’s HP ER Enhancer program has provided cost savings and environmental benefits. Dave Duncan, branch manager of the APAC Shears division, says he has found the product’s shelf life to be particularly beneficial, allowing the business to sell all of what they make. Duncan has also been impressed with the eco-friendly nature of Crafco’s cold patch solution.

“There are fuels in these oils to make them last longer,” he says. “Well, this is a biofuel, so it’s not hazardous and it’s much better for the environment. Our company is always looking for ways to be more environmentally friendly. I think if a lot of the customers in some of the cities knew some of this stuff, they would probably start buying it more.”

Duncan adds that since he can produce this cold patch product at a lower temperature, APAC is able to use less fuel in their burners. The result is lowered emissions during the production process.

At APAC’s Wichita and Augusta locations, estimator and plant manager Stewart Randall says Crafco’s partnership and support have been valuable. Along with being easy to reach for questions, Crafco’s team offers on-site guidance during the mixing process to ensure the product meets standards.

Randall’s main focus when choosing to produce Crafco’s cold patch solution was longevity. After being able to stockpile the product for 6-9 months, Randall is pleased with both the product’s longevity and the associated cost savings.

Ultimately, Crafco’s HP ER Cold Patch is helping asphalt producers and end users streamline their processes, save money, reduce environmental harm and improve safety from the plant to the jobsite.

CLOSING THOUGHT

Ultimately, Crafco’s HP ER Cold Patch is helping asphalt producers and end users streamline their processes, save money, reduce environmental harm and improve safety from the plant to the jobsite.

About the Author:

For more, visit www.crafco.com.

Modern Contractor Solutions, July 2023

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.