By Ruthann Ellis

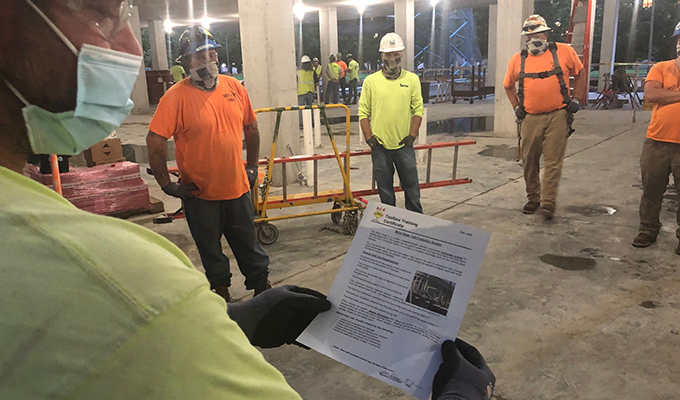

Holding regular Toolbox Talks is an effective way to reinforce the focus on safety for workers. At Ceco Concrete Construction, our crew leaders lead these informational meetings with their crews at least weekly but often daily. The topic is often about a safety issue, safety practice/policy or safe behavior.

Crew leaders probably feel as if they’ve given hundreds of Toolbox Talks on matters like the importance of PPE (personal protective equipment). They may wonder why they must continue to repeat themself. Haven’t we all complained that regurgitating the same information is difficult to do and even more difficult to hear? This attitude is called TTBO: Toolbox Talk Burnout. To avoid TTBO, we need to be creative in how we approach communicating safety to our teams.

Professional athletes do not spend their time at training camps playing the game. Instead, their coaches put them through drills. They spend hours throwing, catching, running plays, and then throwing and running some more. The repetitiveness of the exercises sharpens basic skills until they become a reflex during game time. If you look at a Toolbox Talk as a practice drill that builds the team’s ability to respond automatically in a safe way, you can approach it differently. How you, their coach, conduct the Toolbox Talk is often the single most important factor in motivating employees to turn written information into action. Check out these five coaching tips for more effective outcomes.

- Good coaches prepare. Select a topic that’s relevant to the current work or conditions. Practice reading the written document out loud so that you can measure your pace and tone and won’t stumble over words and phrases. Think about potential objections, questions and challenges that employees may present and be ready with answers.

- Start with the “Why?” Adults need to know WHY they need to know something. This is critical to their ability to internalize information, accept it and then use it. When there is no clear reason for a meeting, adults struggle to make sense of what they are seeing, hearing or learning. Interestingly, the intent of instruction is not always as evident as you may think. If it were, workers would follow the rules and Toolbox Talks would not be necessary. If you don’t know or can’t find the reasoning that reaches them, ask them to tell you why Toolbox Talks happen, and why they think these meetings are important.

- Be brief. The goal is to provide enough detail to let workers know what you want them to do. Most people can only stand to listen for three minutes unless they are part of the conversation, which leads to the next point.

- Involve the worker in the Toolbox Talk. When you provide listeners opportunities to engage actively, both their retention and attitude toward the information improve. Try the following to increase participation:

- Conduct hand-raising polls. (“Raise your hand if you have ever … “)

- Share personal stories of your own experiences.

- Ask someone on the crew to deliver a portion of the talk.

- Conduct “follow-along” demos. (“We are going to inspect our harnesses together.”)

- Ask open-ended questions that require more than a yes or no response.

- Follow up! During the day, stop and ask workers what the Toolbox Talk was about. If they do not know or can’t remember, remind them. If they do remember, ask them why they think the information is essential. Regardless, stay positive and thank them.

CLOSING THOUGHT

Your attitude toward safety talks and the importance of the information shared is critical, and your crews will follow your lead. If you appear noncommittal or complacent about safety, your team will respond in kind. If you show that you are dedicated to keeping everyone safe, they too will be devoted to maintaining a safe work environment.

about the author:

Ruthann Ellis is manager of Ceco Concrete Construction’s Department of Field Training & Development. She can be reached at ruthann.ellis@csghc.com. Founded in 1912, Ceco Concrete Construction is the nation’s leading design-assist structural concrete contractor helping clients build high performing, cost-efficient structures through front-line innovation and technology such as Building Information Modeling to provide the highest quality outcome with the least possible risk. Ceco’s national resources and local presence provide support from schematic design through top-out of cast-in-place concrete structures. With 18 locations across the United States, Ceco is headquartered in Kansas City, Missouri, and is one of several companies comprising the Construction Solutions Group—a group of companies owned by the parent holding company The Heico Companies.

Modern Contractor Solutions, November 2020

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.