Selecting how long a given joint sealant will last before replacement—and what to include for the performance period in lifecycle costing—is not as easy as it may seem. The Seal/No Seal Group continues to investigate joint sealants and the factors affecting their lifecycle through supporting new and ongoing research. As these tests proceed, the results are showing sealants 20 years old still functioning well.

FAIRCHILD AIR FORCE BASE

In 1989, the U.S. Army Corp of Engineers Construction Productivity Advanced Research (CPAR) conducted a sealant performance study consisting of both laboratory and field evaluations. In 2012, Crafco realized that many of the sealant test sections were still in service and performing well. As a result, an additional evaluation was conducted by the same personnel who conducted the earlier evaluations.

ARIZONA LTPP SPS-2

The SHRP LTPP SPS-2 experiment is the largest ongoing concrete research project. Fourteen states originally constructed new concrete pavement test sections as part of this effort. Arizona’s SPS-2, constructed in 1993, is now 20 years old. In March 2013, a field review of the silicone sealant performance was conducted by Applied Research Associates (ARA) engineer Lynn Evans, under contract with the Seal/No Seal Group.

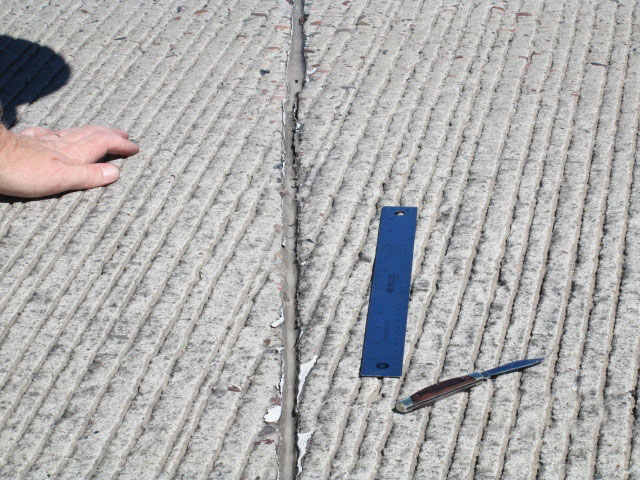

A low modulus hot pour sealant at Fairchild Air force base, again, around 21 years old.

TEXAS TRANSPORTATION INSTITUTE

Dan Zollinger, PhD, Professor of Civil Engineering of the Texas Transportation Institute (TTI), under contract with the Seal/No Seal Group, is evaluating field methods for assessing water infiltration into joints. To study the effect of sealant damage on water intrusion, TTI developed extendable slabs that allow a joint to be pulled apart under controlled conditions to simulate actual joint movement. The last phase of the study will consist of field validation of the techniques and base erosion model validation. If successful, the base erosion model will allow users to determine when and where sealant is cost effective.

WISS, JANNEY, ELSTNER

The Seal/No Seal Group has contracted structural engineering firm Wiss, Janney, Elstner, and Associates to examine potential test methods for evaluating how clean and dry a joint face is prior to sealing, as well as a method for quantifying the bonding of the sealant.

The SHRP LTPP SPS-2 experiment in Phoenix has a 20-year-old silicone sealant.

ARIZONA SPS-2 PCC JOINT SEAL PERFORMANCE

The Arizona Special Pavement Studies (SPS) 2 jointed concrete pavement test site, located on eastbound I-10 between mileposts 106 and 109, was constructed in 1993 with 12 LTPP and 9 ADOT test sections. Each test section includes about 33 transverse joints, spaced at 15 feet, which were sealed using Crafco 34902 non-sag RoadSaver Silicone sealant. Various combinations of base type, concrete strength, slab width, and slab thickness were designed to allow statistical analysis of the contributions of each factor. A March 2013 evaluation was led by Lynn Evans’ team from Applied Research Associates on the condition of the joints and seals in correlation to base type and Portland cement concrete (PCC) strength. ■

Note: The Seal/No Seal Group was formed to respond to the age-old industry question about the value of sealing concrete pavement joints. Its mission is to develop a committed membership that takes responsibility for determining the long-term effectiveness of sealants in concrete pavements. To become involved, call co-chairs Scott Eilken at 708.728.1895 or Charley Grady at 602.524.1334, or email info@sealnoseal.org. All are invited to join and participate in the research. Information on The Seal/No Seal Group and its efforts can be found at www.sealnoseal.org.

For More Information:

For information on joint sealants, studies, and the Arizona SPS-2 PCC Joint Seal Performance Technical Memorandum, view the News and Resources page on the Seal/No Seal Group website: www.sealnoseal.org/news.htm.

_________________________________________________________________________

Modern Contractor Solutions, March 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.

Sealed to Last