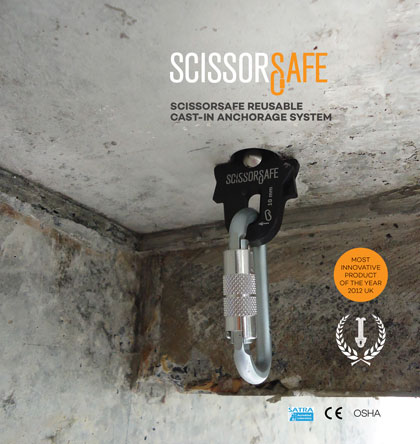

Scissorsafe® is a reusable safety concrete anchor tool which is inserted into a pre-embedded plastic mold placed overhead into the concrete structure without any drilling. Anchor points are placed everywhere needed, allowing the workers to easily move from one work area to another by design, providing safety to workers from the beginning to the end of the project. Simplicity immediately provides the worker with a friendly, easy-to-use fall protection product. The system goes beyond the construction phase by leaving behind anchorage points for the life of the structure to be used by maintenance crews.

PUTTING SAFETY FIRST

Construction projects are planned ahead of time to eliminate errors and speed up installation, providing overall efficiency during construction. So why not put safety measures in place as part of the plan from the beginning of the project?

Why do concrete structures not come with pre-installed safety equipment?

Why do we not install safety measures earlier in the building process?

Why do we put this responsibility on the worker?

SOLUTION WITHIN REACH

The anchor tool’s design delivers added safety to workers by allowing companies to install more anchor points easier, quicker, and more economically, staying in place even after the structure is completed. The concrete anchor tool delivers safety during construction and after the structure is built. Molds are placed everywhere within the building perimeter, and also in elevator shafts, stair cases, and other fall risk areas.

ScissorSafe is an anchorage point for personal fall protection providing a connection point for your lanyard, self-retractable lifeline, or horizontal lifeline in case of a fall.

SIMPLE AND FAST INSTALL

The recycled plastic mold-bottle is environmentally friendly. The mold-bottle cap is nailed to the formwork’s inside-face and then the mold-bottle is snapped onto the cap. This takes place just before the concrete is poured. Once the concrete cures and the formwork is removed, the nailed cap is removed exposing the opening of the mold-bottle. The anchor can then be inserted into the hole and locked into place with a carabiner. Anchor points are recommended every 15 feet or between pillars to maximize coverage where falls can occur.

The exposed hole with the anchor inserted provides an immediate fall protection system, eliminating valuable time spent installing a non-embedded system. This cuts down task time allowing more work to be done, plus workers can easily move from one work area to another by quickly relocating the anchor.

The Scissorsafe anchorage tool’s design resembles a scissor with two blades that move. It is inserted into the mold-bottle that is encased in the concrete. The ends of the tool anchor inside the mold-bottle when the eyes of the tool are aligned. A 10mm carabiner is inserted into the eye and locks the tool in place.

NOTABLE FEATURES

Scissorsafe has notable differences from other safety anchors in that the worker cannot disengage the anchor point without removing the connecting carabiner, which eliminates attachment failures. Its built-in visual impact indicator allows workers to identify when damage has occurred so it can be removed from service. The embedded mold never comes in contact with the rebar, eliminating the risk of moisture, which may cause corrosion; this feature allows the anchor installation in non-reinforced concrete. ■

For More Information: For more information about Scissorsafe and the applications for a personal fall arrest or work restraint system, visit www.safetyseeds.com.

_________________________________________________________________________

Modern Contractor Solutions, June 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.

Scissorsafe