By Del Williams

For developers and architects, maximizing income-generating space for mixed-use commercial projects is critical, particularly when land is limited or expensive. In many cases, the project cannot advance unless the architect can somehow “create space” to achieve the building design and parking density required.

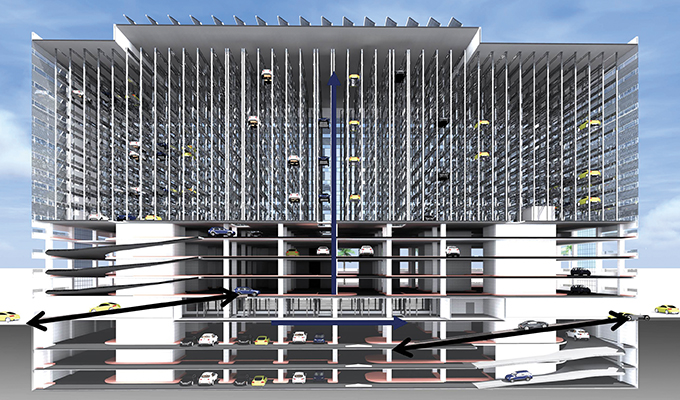

Traditional parking garages, however, waste valuable real estate due to their inefficiency in storing vehicles. As a solution, advanced automated parking systems allow developers and architects to store from 2 to 4 times the number of cars on the same land by eliminating the need for drive aisles, ramps, and space for car doors to open. This provides industry professionals with more options to design projects that can maximize revenue-producing square footage that increases total project value.

Although such technology has been used for several decades overseas, particularly in European urban centers, it has been refined and improved over the last 20 years in the United States. Today, more sophisticated systems are able to park and return 400+ vehicles per hour if designed to do so, which minimizes potential wait time during periods of peak demand. These systems are also designed to deliver unprecedented reliability with 99.99 percent uptime and failsafe redundancy, making them a more viable option than ever for incorporation in building development plans.

AUTOMATED PARKING

Such advanced automated parking technology was essential in helping Gary Tave, a licensed engineer, building contractor, and owner of Square Peg Development LLC. Tave sought to develop a $49 million mixed-use project, called West Bay Lofts, on two city blocks in downtown Largo, Florida. The project, which is a key component of revitalizing the downtown area, will include 123 market-rate apartment homes and 40,000 square feet of ground-floor commercial space in two structures.

Early on, however, the project’s feasibility was in question, primarily due to a lack of needed parking, and spiraling high-rise construction costs that would be required to add the parking required.

“With the project’s constraints in property setbacks, height restrictions, and optimization of net leasable square feet against construction costs, I realized there wasn’t enough available square footage to meet all of the zoning criteria using conventional construction technologies,” says Tave. “The main limiting factor was available parking.”

But when Tave explored purchasing additional land to accommodate a parking structure, he found it was not allowed due to municipal priorities. “We were not able to acquire a piece of adjacent land because the city did not want a large parking lot taking up valuable space downtown,” he says. “So, conventional parking was not an option.”

According to Tave, he also considered adding stories to the building to accommodate several layers of parking. However, this would require building to high-rise construction safety requirements. This would add 25-30 percent to costs, making the project too expensive to pursue.

OPTIMIZING SPACE

As a solution, a growing number of developers like Tave—as well as architects worldwide—are turning to automated parking garages to cost-effectively “free up” space.

When doing research, Tave discovered Robotic Parking Systems, an advanced automated parking technology, by a Clearwater, Florida-based manufacturer of the same name. Before determining that the current technology suited his project’s goals, he was determined to first do his due diligence.

SYSTEM THAT WORKS

Compared to previous forms of automated parking, the advanced technology provides more reliable and consistently faster vehicle delivery. This is due to a unique design that can independently move dozens of vehicles simultaneously on electro-mechanical robots in three axes (left-right, forward-back, and vertically). The result expedites automated parking and retrieval even in periods of peak demand.

In this type of system, vehicle owners drive into a street-level “terminal” at the automated garage, turn off the vehicle, and exit with their keys. Then sophisticated software controls, platforms, lifts, motors, sensors, and other mechanical gear transport the vehicle to an open slot in a multi-story steel shelving system. Different sized bays accommodate larger vehicles, such sedans and SUVs, to improve space utilization. When the owner wants to leave, the system locates the vehicle and returns it to a ground level exit terminal.

“What matters in today’s robotic parking systems is not how long it takes to retrieve one single car, but how long it takes to retrieve 10 cars when 10 people are waiting,” explains Tave. “The multiple exit paths and sophistication of Robotic Parking Systems’ programming helps to quickly get vehicles to their owners.”

Based on a thorough technical/financial review of the technology, Tave is incorporating a Robotic Parking Systems design with 470-vehicle capacity and 240 vehicle per hour throughput in the West Bay Lofts project. The project is expected to be completed in February 2021.

CLOSING THOUGHT

While the initial cost of such a reliable automated parking system is higher than a traditional concrete garage, it is offset by lowering total development costs (including land, construction and soft costs) by as much as 40 percent. Typically, only half the space is required for the same amount of parking, which can significantly reduce the outlay for land purchase. Or, alternatively it can increase the revenue generating development capacity on a given piece of land.

about the author:

Del Williams is a technical writer based in Torrance, California. For more about Robotic Parking Systems, visit www.roboticparking.com.

Modern Contractor Solutions, December 2019

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.