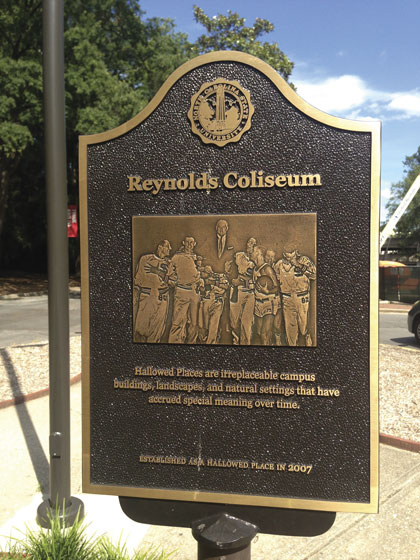

Built in 1949, Reynolds Coliseum is a gathering space for large-scale campus and student events, such as graduations, concerts, and sporting contests, including the 1983 season of Jimmy Valvano and the NC State NCAA championship men’s basketball team. A few years ago, administrators decided it was time to update the “hallowed space,” and modernize the building with air conditioning, a new video board, and various fan amenities.

Seeking LEED Silver certification on the $35 million renovation, the building required a new roof, all new windows and glass doors, along with many other structural enhancements.

PROJECT CHALLENGES

Among the large project’s scope of work was retrofitting the bathrooms with modern tile applications. Specializing in exactly this kind of work, including surface preparation, terrazzo finishing, tile, and other floor coverings, David Allen Company performed a mock-up for the general contractor, Danis, and they subsequently awarded them the work.

Given the building’s historic nature, the David Allen crew did not know what they would find underneath the existing floor covering in the bathrooms. After removing some pieces, they found previous topping slabs had delaminated. Decades old mastic waterproofing was the culprit. In order to properly place the self-leveling underlayment material, they would need to remove all this old mastic first, using mechanical surface preparation methods. The David Allen crew used a regular walk-behind concrete grinder and an edging machine to grind the mastic off near the walls.

After the concrete surface was properly prepared, it was ready for the self-leveling material. In selecting the manufacturer of this material, it was important to David Allen and the building owner to receive a system warranty. Part of the LATICRETE advantage in its product offering is the multi-year system warranty for DRYTEK. It stands out as an industry leader and an excellent point of differentiation. As such, David Allen selected DRYTEK LEVELEX, a self-leveling underlayment flooring system designed to level-out prepared floors for the various floor coverings.

To enhance efficiencies, the crew decided to pump the DRYTEK material instead of hand-mix it. They used a Strong pump to both mix and pump out the material onto the properly prepared concrete surface in the bathrooms up to a depth of 3.5 inches. They then raked it into place and allowed it to cure. The next day, the bathroom floors were level, structurally sound, and ready for the floor coverings. Approximately 600 bags of DRYTEK LEVELEX material were used on the 2,000-foot project.

PROJECT RESOLUTION

North Carolina State University is thrilled with their facility renovations. From the windows to the walls to the bathrooms, their expectations were exceeded. Reynolds Coliseum re-opened in August. ■

For More Information: For more information about the LATICRETE products used in this project, visit www.laticrete.com.

_________________________________________________________________________

Modern Contractor Solutions – September 2016

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.

Reynolds Coliseum Renovation