In last month’s issue, remote control benefits and the technology available for Shielded Metal Arc Welding (SMAW) and Gas Tungsten Arc Welding (GTAW) were discussed. Here’s the rest of the story.

GMAW AND FCAW

Remote technologies for Gas Metal Arc Welding (GMAW) and Flux-Cored Arc Welding (FCAW) are available that operate by way of weld cable controls and allow welding operators to make welding parameter adjustments (e.g., wire feed speed and voltage) at the wire feeder—from up to 200 feet away. These controls, as with the advanced remotes discussed for SMAW and GTAW, communicate through the same cable that carries the welding current from the power source to the feeder, eliminating the need for an extra control cable and with it, an additional tripping hazard.

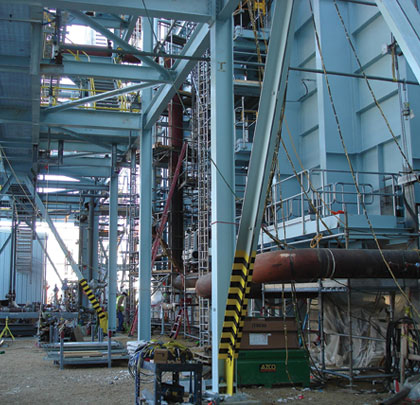

Many contractors in the construction industry employ this remote control technology, as do shipbuilding contractors.

This type of remote technology helps ensure that the signal won’t be blocked by structures on the jobsite and provides the welding operator with more flexibility. It is not necessary to be in the line of sight of the power source to ensure the remote capabilities work. Such a benefit is especially good for welding in confined spaces.

The information communicated from the wire feeder to the power source may include welding power source output command information (amperage/voltage), welding circuit on/off information (power source output contactor control), and/or power source state control (constant voltage/constant current). Welding operators can, in addition to the safety benefits, gain quality control by being able to adjust the actual voltage levels on the feeder’s digital meter.

As with other remote technologies, having these capabilities allows welding operators to spend more time welding as opposed to walking to and from the power source and makes them safer by not having to navigate obstacles on the jobsite. They also experience less strain and fatigue caused by repositioning cables and can be sure that they are not settling for welding parameters that won’t provide the results needed for the job.

Remote control welding technologies have evolved over the years, making it easier to gain the safety benefits of these capabilities in a cost-effective manner.

ADVANCED WELDING PROCESSES

Advanced welding processes like modified short circuit GMAW welding and Pulsed GMAW welding are becoming increasingly popular as companies—particularly those serving the refinery, petrochemical, power generation, and HVAC industries—seek to improve quality and productivity.

Remote control technologies for these processes are available to give the welding operator not just the ability to change weld parameters at the weld joint, but also the ability to change the weld processes at the touch of a button.

Welding operators simply connect the power source with a specially designed “smart” wire feeder to gain full remote control capabilities, including process selection, material type and wire diameter, gas type, wire feed speed, and voltage. The power source automatically shifts all controls to the feeder when connected, eliminating the need to string and manage the clutter of the additional control cables.

The wire feeders with these remote technologies extend the distance from the power source 200 or more feet away from the power source (without line of sight issues). They also actually generate and control the welding process, which ensures the waveform extends to the point of use in an optimal state because it is only traveling the length of the GMAW gun cable. Previously, cables for advanced processes would carry the waveform from the power source over long distances to the feeder, resulting in a distorted waveform that could affect arc performance and weld quality. These cables could also be quite expensive to purchase and to repair should they become damaged.

Most importantly, by featuring one less cable (the communication cable) and giving the welding operator total process control at the weld, such remote control capabilities are again increasing safety by reducing travel to and from the power source.

MAKING THE DECISION

Deciding between remote control technologies depends largely on the welding processes needed for a given application, but offers the same benefit on every one: productivity, quality, and safety.

By removing the need to travel to and from the power source, they reduce downtime that can negate productivity gains and eliminate the hazard of trips and falls occurring while welding operators navigate what are often cluttered work corridors. They also help prevent welding operators for settling for less than optimal parameters that could lead to poor weld quality.

Combined, these three benefits (productivity, quality, and safety) can help positively impact the completion of projects that are often driven by tight deadlines, while also creating a more functional and safer jobsite. ■

For More Information:

Joe Ryan is a marketing segment manager, process pipe welding with Miller Electric Mfg. Co. For more information, visit www.millerwelds.com.

_________________________________________________________________________

Modern Contractor Solutions, March 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.

Remote Control Welding Technologies Part II