As we head into construction’s busiest time of year, contractors and suppliers operating in the residential and commercial building supply arena are turning to technology to keep pace with the highly-variable and highly-mobile construction environment. From automated fleet routing and scheduling to paperless proof of delivery, construction professionals are eschewing cumbersome manual and paper-based processes in favor of mobile technology that streamlines the supply chain, alleviates claims management demands, and dramatically improves the customer experience.

IT’S COMPLICATED

Construction is a complex and highly-dynamic business. Managing the delivery of materials and equipment to the jobsite can be challenging, with lead time for ordering and delivery often less than 24 hours. Region-specific requirements, a wide range of trucks (e.g., semi-trucks, vans, boom trucks, dump trucks) and off-loading equipment (e.g., fork lifts, cranes, telescopic handlers, hoists), and different materials with varying loading and unloading times further complicate the delivery process.

On the construction site, work needs to be properly sequenced and coordinated with the delivery of materials and availability of crews—a tall order for contractors juggling multiple suppliers. Similarly, suppliers delivering building materials and equipment to the jobsite face multiple logistical challenges, managing unforeseen changes in customer demands, weather, inventory requirements, and more.

AUTOMATION DRIVES PERFORMANCE

Contractors and building suppliers are recognizing that supply chains that are bogged down with traditional paper and clipboard processes simply can’t keep pace anymore with the dynamic nature of construction operations. These outdated manual practices are error-prone, highly inefficient, and an impediment to achieving high standards of customer service, especially during peak season.

The solution? Real-time route planning and dynamic appointment scheduling that can be readily integrated with a wide variety of enterprise systems (e.g., OMS, CRM, ERP, WMS, customer portals/websites, etc.) to provide an end-to-end solution for the full order-to-cash workflow. These types of technologies help contractors by driving up the delivery performance of their suppliers. By moving the ability to plan deliveries, schedule appointments, optimize routes, dispatch orders, and communicate with drivers to a completely paperless environment, automated fleet routing and scheduling boosts on-time delivery performance and capacity utilization while driving down transportation costs. It’s a win-win for suppliers and contractors.

Mobile technology provides contractors with accurate real-time visibility into the details and timing of construction site deliveries, including providing automated exception notifications. As a result, tasks, like reassigning deliveries, managing exceptions, and responding to customer changes on the fly, can be done virtually instantaneously.

Plus, with automated ETA updates and real-time visuals to confirm current truck locations, suppliers can relay ETA information to contractors without distracting their drivers with inquiry calls or texts—an important safety consideration.

ALLEVIATING CLAIMS MANAGEMENT HEADACHES

Claims management can be a painful experience for contractors and suppliers, alike (and homeowners, in the case of residential construction). Mobile proof of delivery (POD), however, takes the guesswork and hassle out of managing inevitable jobsite claims.

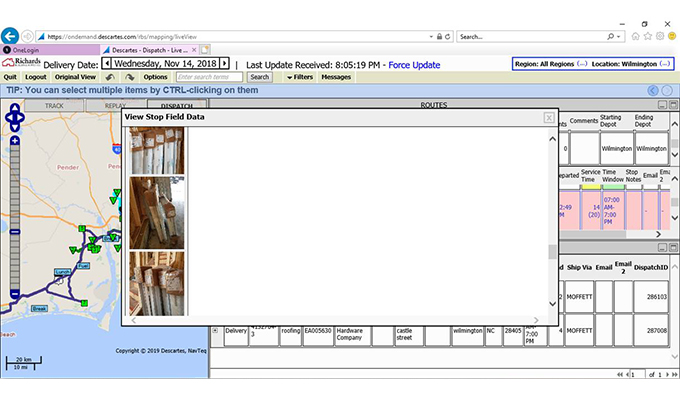

The process is simple. With mobile devices, drivers have everything they need to wirelessly confirm deliveries and other details in real time. Drivers capture a signature electronically to signify the safe arrival of items at the construction site and take digital pictures to confirm condition of goods and that no items are missing. Data is collected, consolidated, and transmitted wirelessly. Electronic POD helps efficiently resolve potential claims while mitigating fraudulent ones—saving all stakeholders both time and money.

Ron Guzior, CEO and president at Richards Building Supply (RBS), a wholesale distributor of building materials, noted that electronic POD is a lifesaver for claims management at his organization. “A contractor notified us that several windows from a large order were missing but digital photos proved they were delivered, and the customer found them onsite. In another instance, ‘before and after’ photos removed RBS from the accusation of damage to a driveway and the contractor was able to identify the real culprit.”

In addition to simplifying delivery claim resolution, mobile POD also shortens billing cycles, accelerates revenue recognition, and ensures expedient processing of returns.

CUSTOMER EXPERIENCE IS PARAMOUNT

In the midst of tight budgets, strict deadlines and labor shortages, contractors are striving to deliver an exemplary customer experience for the homeowner or commercial client. Similarly, suppliers of building and construction materials recognize the importance of differentiating their organization in a highly competitive field by providing a superior level of customer service to contractors.

The combination of dynamic appointment scheduling, automated delivery route planning, and real-time updates on mobile devices is the ace up the sleeve of building suppliers and contractors—and the secret to sustaining their symbiotic relationship and enhancing the customer experience across the field.

RESULTS SPEAK FOR THEMSELVES

Wholesale building distributor RBS invested in fleet scheduling and delivery route planning software to help ensure consistent, on-time delivery to its growing customer base—especially critical during its peak summer season.

In addition to more intelligent route planning, RBS drivers access delivery schedules using a mobile device. Real-time updates from GPS-tracked vehicles provide visibility into driver availability and location to monitor delivery times against customer expectations. With mobile technology, contractors know exactly what material has arrived and when, so they can keep construction projects on track. Plus, orders can be changed easily if weather or other unforeseen complications interfere with planned work and associated scheduled deliveries.

Nicholas Chesna, the fleet assistant manager at RBS, remarks, “We are in a much stronger position to drive realistic and reliable delivery schedules, increase the number of deliveries we can make each day, and ensure delivery time windows are tightly coordinated with customer requirements.”

CLOSING THOUGHT

Indeed, in this data-driven, mobile-focused world, the combination of mobile technology and a paperless supply chain is a viable competitive weapon in the distribution-intensive building supply and construction industry. Is your organization ready to embrace technology to master your supply chain and elevate the customer experience?

About the author:

Sunil Mathew, director, Industry Strategy at Descartes Systems Group, which focuses on mobile technology serving as a secret weapon in the construction industry. Mathew is responsible for the identification of trends, solutions, and processes to enhance Descartes’ Routing, Mobile and Telematics (RMT) offering.

Modern Contractor Solutions, August 2019

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.