As wildfires rage across the American West, hurricanes intensify in the Southeast, and insurance markets tighten nationwide, the demand for fire-resilient, climate-ready buildings is no longer theoretical—it’s urgent. What was once seen as rare or exceptional is now becoming the new norm, both in the U.S. and globally. In the metal construction sector, leaders are taking note and taking action.

In a recent MetalCon Online webinar, a high-caliber panel of experts came together to unpack the intersection of building science, climate policy, material innovation, and insurance economics. From testing standards and code lag to community planning and insurance incentives, the discussion emphasized one central theme: Metal has an integral role to play in the future of resilient construction.

Here are key takeaways from the conference:

CODES ARE CATCHING UP—TOO SLOWLY

Recent catastrophic fires and storms have revealed painful shortcomings in how the construction industry approaches resilience. Many buildings, especially older ones, were not designed to withstand the hazards resulting from today’s extreme climate events. While building codes are evolving, the panelists were unanimous in a critical point: They’re not keeping pace with the climate.

“The fact that there has been such disaster, it shows you cannot rely on the existing codes and standards,” says Dick Davis, former fire engineer and technical specialist with FM Global. “We have to look closely at the science and figure out what materials to use whether it is residential, commercial, or industrial construction.”

Alan Scott, FAIA, director of sustainability at Intertek adds, “Recognize these hazardous events can happen anywhere. What happened in the past is not necessarily indicative of what will happen in future occurrences, so assessment is required.” Scott shared a sobering example of a California apartment building that highlighted the flaws in current fire-risk mapping. Depending on which map you used, the building was shown in both a low-risk and high-risk zone—yet it ultimately burned to the ground in the recent wildfires.

Anoush Brangaccio, senior policy advisor at the Florida Office of Insurance Regulation, explains the structural delays in the code-update process. “The building code is updated every three years,” she says, adding that some states lag even further. Not all states have uniform building codes, and if they don’t, it’s time they consider implementing one.

Davis confirmed that reality: “I’ve seen situations where some states were still using the 2003 code when the 2015 code came out. That’s how backlogged it can get. And people need to remember that code requirements are minimum requirements. There’s nothing wrong with exceeding those requirements.”

METAL’S EDGE

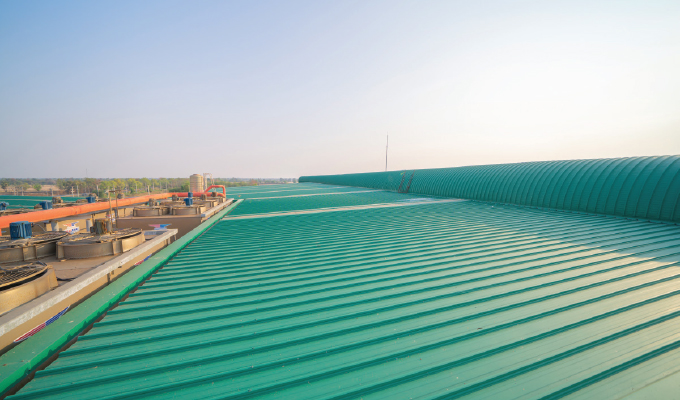

While no single material can solve every risk, metal stands out as one of the most effective front-line defenses—especially in fire-prone regions.

“Metal roofing would be a wonderful solution for areas that are prone to fire, wind and hail,” says Brian Partyka, vice president of business development of Carlisle Companies. “Will they dent in hail? For sure, they’ll dent in hail…but the metal roof is going to have a Class A fire rating.”

He notes that organizations like the Insurance Institute for Business & Home Safety (IBHS) are pushing for more rigorous standards. “There’s a wildfire prepared neighborhood program by IBHS… and metal roofs are mentioned in that as a non-combustible Class A fire rated [product].”

But Partyka is careful not to oversell. “It’s not the end-all be-all…I don’t want to say this is the cure, and everybody should have a metal roof. I think it will help to eliminate some of the possibilities of ignition.”

Davis explained why not all metals perform equally in fire scenarios: “The melting temperature of aluminum is about 900 to 1,200 degrees Fahrenheit; copper is approximately 2,000 degrees; and steel is north at 2,600 degrees. Actual flame temperatures vary from 1,000 to 2,000 degrees.”

HOLISTIC DESIGN AND SYSTEM THINKING

The consensus was clear: Resilience isn’t about one product, one material, or one code update—it’s about the system.

“Whether we’re talking about fire resistance or hurricanes or floods,” says Scott, “designing buildings that have overall greater sustainability, like designing for passive house type standards … means you’re both resilient against those hazard events and … have a building that’s less expensive to operate, uses lower utilities, and has a lower carbon emission.”

Davis drives the point home with a stark reminder: “If that fire gets inside the building, no matter how it gets in there, you could destroy the whole building.” He emphasizes the need to consider the entire building envelope to protect the structure from wildfire exposure—the roof, the walls, the window systems, soffits, and even vent mesh. He adds that people often overlook the importance of the windows and should use fire-rated glass, which includes heat-blocking gel layers, or double-pane tempered glass, which withstands high heat better than standard glass. “Think of the window as a system; it’s got a window frame.” Steel is ideal, while vinyl should be avoided unless reinforced with steel due to its low melting point.

WHERE TO GO FROM HERE

As disasters evolve, who’s responsible for keeping the industry ahead?

“I don’t like to put too much reliance on waiting for the codes to change to solve all the problems,” says Davis. “If a celebrity in Southern California wants to build a $5, 10, $20 million house, I would tell him to first engage a fire-protection engineer and a structural engineer to give him some guidance. If he’s going to spend that kind of money on a house, build something that’s actually going to last.”

Scott suggests a multi-layered approach: “It’s state and local policy and codes. It’s urban and regional planning and zoning… all of those layers have to fit together to create the complete package of resilience.”

Brangaccio adds, “If we’re going to ask our consumers and our residents to do this, they need to get something back to help offset it.”

That’s where METALCON, the only global event dedicated to the application of metal in construction and design, comes in.

“We at METALCON have a role in this—and our role is to keep this communication going,” says moderator Frank A, Stasiowski, co-founder of MetalCon and CEO of PSMJ Resources Inc. in closing. “We need to make sure that the innovation happening in labs and factories is matched by awareness in the field—and that’s a communication challenge we’re ready to take on.”

for more information

From code compliance to climate resilience, METALCON’s educational programming uncovers how the fire-resistant and non-combustible properties of metal are reshaping building design in high-risk areas. For more, visit www.metalcon.com.