Freshly poured concrete contains a lot of water for curing. Even after the initial curing phase is completed, there is still water left in the concrete slab. This free water can cause problems when applying sealers, coatings, and other floor coverings directly on the concrete slab. To avoid moisture problems, the moisture in the concrete needs to be within certain limits. Floor covering manufacturers provide those limits. If it is not possible to stay within those limits, a vapor barrier needs to be installed to protect the floor covering.

Over the years, people have used different measuring methods to find out how much moisture is in concrete. While some methods are not reliable enough to eliminate floor covering failures, the RH in-situ probe measurement has gained popularity because it can eliminate failures.

MOISTURE IN CONCRETE

Concrete hardens and becomes strong as it incorporates water into its cell structure. That process can take a long time to be 100 percent completed. Until then, the concrete slab releases moisture into the floor covering, or, if uncovered, continuously releases moisture into the air. The surface of the open slab dries first, but the center can still hold more moisture. Covering the slab traps the moisture inside where, over time, the moisture distributes itself evenly throughout the slab. The core moisture is now lower than before and the surface moisture is higher.

Elevated surface moisture can affect a floor covering and cause unwelcome damage. The result could be a cupped hardwood floor. Wood is like a sponge pulling any excess moisture out of the concrete slab until reaching equilibrium. Installing a proper vapor barrier or allowing the concrete to dry longer would be a preventive measure.

There is one more consideration. Concrete is a hygroscopic material. Unless sealed off from the environment, concrete will absorb water if available. For example, if a slab on grade is not properly sealed off, ground water can infiltrate the concrete, migrate into the floor covering, and ruin it. Another example of the hygroscopic nature of concrete is how fast water spills are absorbed into an unsealed concrete floor.

To protect against unwarranted claims, many floor coverings manufacturers now include moisture testing in their warranty requirements. That includes resilient floor coverings, such as hardwood, bamboo and engineered floors, cork floors, carpets, linoleum, or tile. Epoxy sealers and other coating manufacturers also specify moisture conditions. If the required moisture testing is neglected, the warranty could be lost.

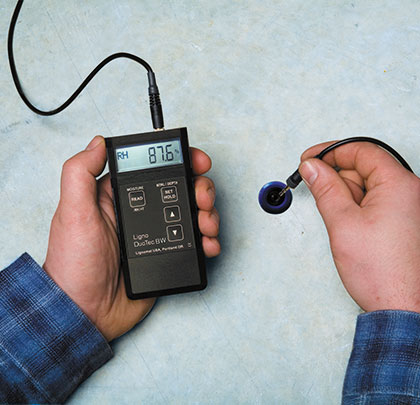

Feature Image: The Ligno-DuoTec BW is one of three moisture meters from Lignomat, which can be used for RH in-situ probe testing in concrete.

Above: The illustration shows the RH in-situ probe test. The sleeve seals the concrete. Moisture is only allowed to enter the sleeve through the open bottom.

MOISTURE MEASURING METHODS

The first methods for moisture testing of concrete were pin and pinless meters. However, meters have a limited measuring depth. Plus, meters measure the moisture in the concrete and not the evaporation out of the concrete. The results from pin and pinless meters are not fail-proof or a reliable indicator for deciding on installing floor coverings.

The National Wood Floor Association (NWFA) recommends the use of handheld moisture meters, pins or pinless, only for quantitative readings, by which high and low moisture areas can be found. If the test is performed to determine whether to install a floor covering, the NWFA recommends the Calcium Chloride test or the RH in-situ probe test.

Manufacturers of floor coverings are more frequently recommending the RH test; it has proven most reliable. The RH test measures the moisture evaporation at a depth of 20 percent of the slab thickness if a slab dries from both sides and at a depth of 40 percent if the slab dries from one side. Testing at these depths gives the same results as if the slab would be covered with a low-permeable floor covering.

The Calcium Chloride test measures the evaporation from the concrete. However, the test results only take into consideration about ¼ inch of the depth of the entire slab. Another disadvantage of the Calcium Chloride test is that the measurements depend on the relative humidity and temperature in the room. Evaporation rates vary whether the ambient relative humidity is high or low.

RH IN-SITU PROBE TEST

ASTM F2170 describes applications and procedures of the RH in-situ test. The test is performed to determine whether to install floor coverings or coatings. Moisture evaporating from concrete floor slabs can affect the performance of resilient and textile floor coverings and coatings.

Inserting a sleeve into a predrilled hole in the slab allows measuring the internal relative humidity and temperature at a defined depth. According to the ASTM standard, the sleeves have an opening at the bottom. Two or more fins are located close to the opening at the bottom. If the meter is not connected, a cap with seal ring is covering the sleeve to obtain readings.

The ASTM standard still requires a 72-hour waiting period to record final measurements; however, you can conduct a pretest to determine if the moisture of the slab is within the desired range.

For the pretest, first drill one or two holes. Next, clean and vacuum the holes and insert the sleeves and the RH Probes, then cover the hole with the cap. A few hours later, obtain preliminary results by connecting the RH meter to the probe in the sleeve. If readings are above the desired moisture range at that time, the slab needs more time to dry. If readings are close or lower than the desired range, leave the probe in for the duration of the test.

The RH in-situ probe test has been used to determine slab moisture for several years and has become more and more popular. Many manufacturers of floor coverings and coatings give permissible RH values for their resilient floor products. ■

About The Author: For more information, contact Grete at sales@lignomat.com, or visit www.lignomat.com.

_________________________________________________________________________

Modern Contractor Solutions, August 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.

Measuring Moisture in Concrete