one ready-mix supplier embraces new technology to better serve its customers

During the COVID pandemic, companies had to come up with new ways to keep their employees and customers safe and keep contact to a minimum, or not at all. For producers and contractors in Indiana, a change was coming down from the state whether they were ready for it or not.

PAPERLESS TRAIL

In April 2020, when the Indiana Department of Transportation (INDOT) stopped requiring paper tickets at the time of delivery on a project site, it offered contractors three different options if they could not safely provide paper tickets. Companies could switch to e-ticketing, send a copy or image of the ticket via email or text, or an inspector could utilize INDOT’s Load Tracking Log to record the needed load information if the site had limited or no cell service.

Irving Materials Inc. (IMI ), a building materials producer based in Greenfield, Indiana, chose option one and decided to fast-track a plan to eliminate paper tickets completely. IMI had been in discussions with INDOT about implementing eTicketing a few years prior to the pandemic.

“The state of Indiana was very interested in going to a paperless ticket mainly because of their storage problems,” says Keian Roudebush, IMI project manager. “There were a lot of logistics involved in paper tickets. Between storing and filing for hundreds of locations, it was very hard to not only retain but access that information afterward.”

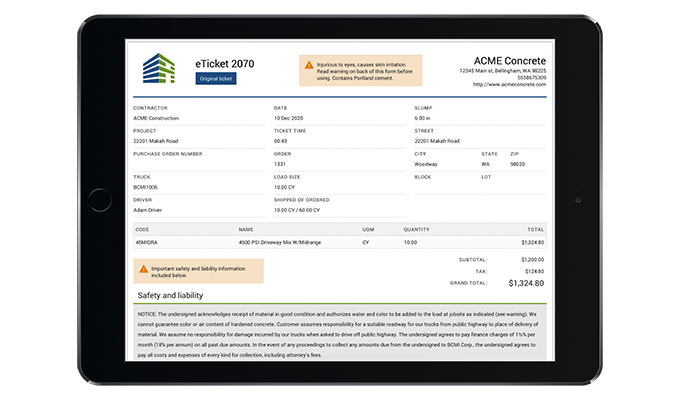

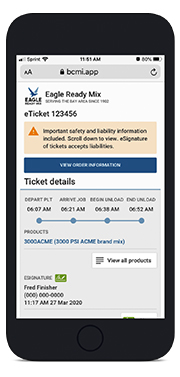

IMI has also been working with BCMI Corp., an industry-based technology provider that offers cloud-based mobile software tools and apps for bulk construction materials producers, to implement its eTicketing solution. IMI’s customers were already using BCMI’s Material Now application, which allows users to track and submit orders from a mobile phone or tablet.

With the eTicket and eSign components, contractors can receive and sign eTickets on their own devices, track job-site activity in real-time, share information across project teams, and download or print ticket PDFs and spreadsheets on demand.

By April 1, 2020, IMI had an eTicket to offer its customers. IMI’s goal was to eventually cut off paper completely by August 2020.

ETICKET EDUCATION

Initially, some people were apprehensive about the change because it was happening so quickly, Roudebush recounts. However, once they saw the benefits they came around. “The industry has benefited from people pioneering the eTicket because we know it’s a faster and better method to distribute information,” Roudebush says. “People who don’t have access to the jobsite are now able to see what’s going on in real time.”

When using the eTicket + eSign solution, customers have two options. A customer can use the Material Now app to access eTickets as part of the entire project record or they can receive an eTicket link by text or email. The biggest challenge initially for IMI was confirming accurate customer phone numbers so an eTicket link could be sent with every order.

For those new to the eTicketing process, IMI provided educational opportunities by holding multiple meetings with agencies such as the Kentucky Transportation Cabinet, Tennessee Department of Transportation, and individual DOT districts to help them understand the process.

“There were struggles with people who just didn’t understand how it worked,” says Roudebush. “It was a team effort to make eTicketing go smoothly for everyone involved, and ultimately to make it easier to do business with IMI .”

CONVENIENT EFFICIENCY

The launch of the eTicket changed the entire process for many operations by formalizing the delivery of a ticket, which typically accompanied the truck beforehand. Now, it’s sent in real time, prior to the truck arriving at the jobsite.

Another bonus of eTickets was efficiency. Employees no longer have to spend time searching for or spend time and money printing tickets.

“There was a huge cost to the customer that they never calculated- how much time it takes to manually process tickets,” Roudebush adds.

He explains how customers used to take an entire pile of paper tickets and spread them out on the table to do their reconciliations, sometimes having to wait for the field supervisor to bring in their tickets.

“Now when they are reconciling invoices and tickets, they’ve gone from searching for tickets to having them at their fingertips,” says Roudebush.

Customers also have the ability to digitally download and accept, or eSign, tickets, which, Roudebush says, is a great way for a customer to close the loop on the delivery cycle for themselves.

IMI began to add different features to the eTicket based on customer requests, including job numbers, load times, time stamps, and batch weights. The digital eTicket record is updated in real time, so now it can include things, like water added at the jobsite, and a weather stamp at the time the concrete is placed. Additionally, this new process has helped overcome language barriers by allowing customers to view eTickets in Spanish.

IMI also sends an eTicket PDF, allowing customers to not only have a digital record of every load but also have a ticket document that they can print if needed.

FEWER MISTAKES

An ongoing industry challenge with tracking tickets is related to large jobs that have concrete delivered from multiple plants. Although eTickets hasn’t completely solved the problem, it is helping in getting closer to a solution.

“Before, it was a piece of paper sitting on a fender and they were counting tickets,” Roudebush says. “Although the same thing has to be done with eTickets, at least now the customer can see the truck’s status and track what tickets have been delivered.”

The number of mistakes has also decreased. Customers can see if a delivery address or project name is incorrect even before the product is delivered. Previously, the mistake would not have been noticed until the customer received an invoice. It has created more real-time invoice preparation rather than problem reporting.

Roudebush comments that providing more timely customer service and sharing real-time information helps keep customers’ books current and customer satisfaction high.

With eTicketing, IMI’s customers are seeing the benefit of tracking not only individual loads and tickets but all their orders and projects in the Material Now app and web portal.

FUTURE OF ETICKETING

Roudebush sees a merging of technologies. The logical next step to delivering digital tickets is digital invoicing. Contractors could then automatically import invoices into an accounting system, such as QuickBooks. Roudebush also sees online “ePay” options becoming easier.

“I think there will be a convergence of ticket information, invoicing, and billing,” predicts Roudebush. “eTicketing is just the beginning.”

FOR MORE INFORMATION

For more about eTicketing, contact BCMI Corp at www.bcmicorp.com.