According to the American Road & Transportation Bridge Association, 36% of U.S. bridges—nearly 224,000—need repair work and 78,800 bridges should be replaced. That’s enough road and bridge work to keep contractors busy for years to come.

Last year, the U.S. Bipartisan Infrastructure Law was signed, making nearly $27 billion available in the coming years to repair approximately 15,000 bridges. With this amount of work and funding, it’s no surprise that contractors are looking for equipment solutions that expedite road and bridge work while keeping safety and efficiency top of mind. Hydrodemolition is one such solution that has risen in popularity when it comes to road and bridge projects.

WHY HYDRODEMOLITION?

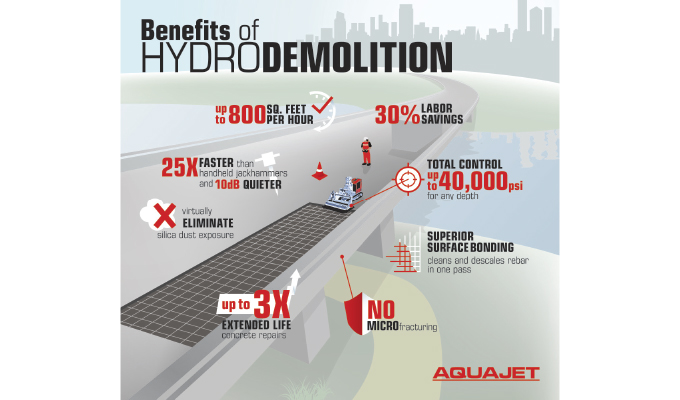

Hydrodemolition removes deteriorated and damaged concrete with robotically manipulated high-pressure water jets as powerful as 40,000 psi. When a Hydrodemolition robot’s high-pressure water jet hits the concrete, it widens existing pores, causing the concrete to explode and separate.

The method offers numerous advantages, starting with an impact-free process that eliminates vibrations and the risk the microfractures. Hydrodemolition also cleans and descales rebar without damaging it and provides a rough bonding surface that is ideal for applying new concrete. These factors extend the lifespan of the structure, making the repair a cost-effective investment.

INCREASED EFFICIENCY

Along with the structural advantages, Hydrodemolition offers a faster way to complete work—up to 25x faster than handheld tools—and it requires less labor.

One operator generally controls the machine and can complete concrete removal tasks as fast or faster than multiple workers. For example, some Hydrodemolition robots can remove as much as 800 square feet of concrete bridge deck at a depth of 4 inches per shift, a fraction of the time it would take a crew with handheld breakers.

In addition, a Hydrodemolition robot can handle much more than the flatwork, helping contractors get more from a single machine. With the right accessories, it can remove concrete on any part of the bridge, including columns, girders, parapet, and the underside. An extension kit with an elbow, for example, extends the Hydrodemolition robot’s reach 8.2 feet below the robot’s tracks. It can also bend to access hard-to-reach areas, such as the side of the bridge, allowing the robot to stay on the deck without dismantling the bridge railing. Aquajet also offers rotating tools for surface preparation and membrane removal and a circular powerhead for columns, further increasing versatility.

IMPROVED SAFETY

Hydrodemolition robots also provide a boost in operator safety. The compactness of the equipment allows it to fit into one lane, minimizing traffic impact and lowering the risk of accidents. The remote-controlled capabilities of these machines also allow laborers to monitor their work at a safe distance from flying debris and edges that pose a falling risk. The elimination of the need to stand next to a ledge also means contractors can minimize the need to set up fall protection systems.

This isn’t the only safety benefit both contractors and operators will appreciate. Handheld water jetting and pneumatic tools put great physical strain on workers, increasing the risk of injury. A worker using a 40,000 psi hand lance, for example, must constantly fight up to 52 pounds of back thrust (at a flow of 5 gpm) for normal operation. Meanwhile, a worker using a jackhammer is exposed to vibration and runs the risk of developing hand-arm vibration syndrome, which causes debilitating, painful numbness, and tingling sensations in the fingers, among other injuries. The physical exhaustion workers experience from manual labor translates to less productivity and greater cost for the business owner. Alternatively, the cutting-edge technology of Hydrodemolition robots combats worker fatigue and reduces the chance of injuries.

Hydrodemolition methods also minimize worker exposure to silica dust and its risks of causing the development of lung cancer, silicosis, kidney disease, and more. Since Hydrodemolition uses water to remove concrete and keeps the operator a safe distance away with remote operation, it virtually eliminates the risk of silica dust.

CLOSING THOUGHT

With billions of dollars’ worth of work needing to be completed and labor difficult to find, investing in the right technology is one of the best solutions for completing more work. With the ability to protect the safety of the workforce and create long-lasting repairs, Hydrodemolition allows contractors to work smarter, not harder.

For More Information:

Aquajet is known as the industry leader in Hydrodemolition machines and solutions, both in terms of quality and volume. The company’s headquarters and production facilities are in Holsbybrunn, Sweden. Similar to Brokk, Aquajet sells globally. Brokk Inc. is the North American distributor for Aquajet. For more, visit www.aquajet.se or www.brokk.com.

Modern Contractor Solutions, September 2022

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.