There are hundreds of federal Occupational Safety and Health Administration (OSHA) regulations that apply to the construction industry, but you might be surprised to know that none of them directly pertain to working in the heat—yet. While some states like California have voluntarily adopted heat stress standards, the U.S. Department of Labor (DOL) has yet to do so. But those regulations are likely coming soon. This article gives an overview of the latest proposal from DOL about a potential heat stress standard and what construction businesses can expect.

In August 2023, DOL issued its “Heat Injury and Illness Prevention in Outdoor and Indoor Work Settings Regulatory Framework.” The purpose of the framework was to give stakeholders a sense of what an OSHA heat stress standard might ultimately look like and provide a menu of options. The framework outlines two key approaches to a potential heat stress standard. First, the standard would be “programmatic” and could require employers to create a plan (i.e., program) to evaluate and control heat hazards in their workplace. Second, the standard would also set specifications related to heat exposure levels.

WRITTEN PROGRAM

DOL envisions requiring employers to develop their own written Heat Injury and Illness Prevention Program (HIIPP). DOL is considering the precise parameters for the HIIPP, but generally employers will need procedures for (1) identifying heat hazards, (2) implementing engineering safeguards (i.e., eliminating the hazard), (3) implementing administrative safeguards (i.e., changing work practices), (4) responding to “high-heat,” (5) responding to emergency medical situations, and (6) training. Employers would be required to review their HIIPP at as-yet-undefined intervals.

IDENTIFYING HEAT HAZARDS

Any heat stress standard adopted by DOL will likely require monitoring of the temperature by employers. When the temperature reaches a certain “heat trigger,” additional engineering and administrative controls would be required.

For employers with outdoor jobsites like those in the construction industry, the HIIPP must include policies for monitoring weather conditions by either (a) tracking local forecasts or (b) monitoring conditions at the jobsite on a periodic basis. The critical metric will be the heat index, which measures both the ambient temperature and humidity. For those employers in hot climates, they may elect to just assume the site condition meets the heat trigger and instead opt to enact the procedures discussed below as a matter of course.

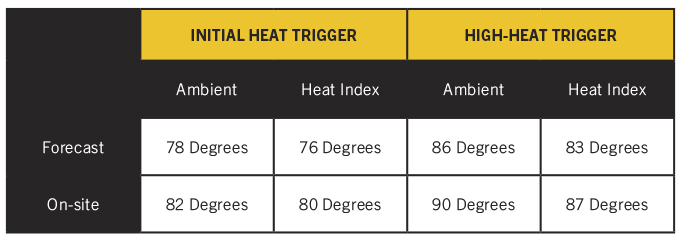

The heat triggers (discussed further below) will vary based on whether an employer chooses to monitor the local forecast or the actual jobsite conditions on the assumption that jobsite monitoring will be more accurate than simply reviewing the local forecast.

HEAT TRIGGERS

Among the more controversial elements of the new proposed heat stress standard are the temperature triggers. DOL envisions both an “initial heat trigger” and more drastic “high-heat trigger.” If an employer chooses to monitor conditions on the jobsite instead of relying on the forecast, there will be a higher trigger that will likely require control procedures for only those hours within the trigger temperature. Forecast monitoring, which DOL assumes is less accurate, will have a lower heat trigger and will require controls throughout the day. The heat triggers proposed by DOL are provided in the chart above. Note well that forecast monitoring will have a heat trigger with a heat index as low as 76 degrees.

SAFETY CONTROLS

When the temperature reaches one of the heat triggers in the chart above, employers would be required to implement various measures to protect workers from heat stress. The framework distinguishes between engineering controls (which are meant to eliminate the heat hazard) and administrative controls (which are meant to change work patterns to avoid injury).

Engineering controls for outdoor worksites primarily revolve around “cool-down areas.” The final regulation might include requirements to provide a cool-down area made of natural shade, tents, or portable, air-conditioned trailers and would need to be close to the jobsite with enough room for all employees.

Administrative controls would include providing drinking water to employees. While OSHA standards already require water to be made available to employees, the new heat stress standard could govern things like the location, temperature, and quantity of water which must be made available to employees once a heat trigger is met. Administrative controls might include new rules for acclimating employees to the ambient temperature, including gradual acclimatization where an employee works a reduced schedule over a number of days until properly acclimated. Lastly, and perhaps most importantly, the final regulation might require mandatory rest breaks, including a 10-minute break for every two hours worked, even at the initial heat trigger of 76 degrees.

TRAINING & RECORD KEEPING

The final DOL heat stress rule would likely include new training obligations for employers, including informing employees about the signs and symptoms of heat stroke, how the temperature at the worksite is monitored, and the risk factors for heat injury. Employers would also be required to train supervisors on how to monitor employees for heat stress.

As with most regulations, DOL envisions a record-keeping requirement to document compliance. Employers would be required to keep records of their efforts to monitor the temperature and heat triggers, any heat-related injuries and temperatures and work conditions at the time of injury, and a log of all efforts to acclimatize employees.

CLOSING THOUGHT

DOL is well on its way to developing a heat stress standard. The standard will likely impose significant new obligations on construction employers. Now is the time to begin coming to grips with that reality and planning for the future.

About the Authors:

Luke J. Farley is a construction lawyer and partner in the Raleigh, North Carolina, office of Ellis & Winters LLP. His practice is devoted to contract disputes, mechanics’ liens, bond claims, and OSHA citations. He also assists clients with contract negotiation and project-level advice. He can be reached at luke.farley@elliswinters.com.

Dixie T. Wells is a partner in the Greensboro, North Carolina, office of Ellis & Winters LLP. She represents clients in lawsuits involving engineering issues, higher education law, complex commercial transactions, and products liability. She is a member of the Construction Law and Litigation Committee of the International Association of Defense Counsel. She can be reached at dixie.wells@elliswinters.com.

Modern Contractor Solutions, November 2023

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.