Engineered slabs drive down warehouse operating costs and increase flexibility

The increased popularity of online shopping is driving demand for more commercial warehouses and distribution centers. According to Dodge Data & Analytics, during the past 2 years, the number of one-million+ square-foot commercial warehouses breaking ground has doubled. Together, these new construction starts span more than 64.1 million square feet.

Warehouse and distribution center tenants have high expectations when it comes to technology, operations, and space utilization, so brokers and developers are continually looking for inventive ways to make their projects more desirable.

DUCTILCRETE® engineered slab systems can bring corporate tenants a number of benefits, including:

- Driving down warehouse operating costs

- Reducing its carbon footprint

- Increasing warehouse flexibility and allowable loads

DRIVE DOWN COSTS

Ensuring the longevity of the warehouse structure and reducing maintenance costs starts with the building design phase. According to a report by the university Politecnico di Torino about strategic factors influencing warehouse maintenance costs, “to create cost savings, it is important to design and build maintenance cost-efficient workplaces or to select constructed facilities that were designed for this objective.”

To that end, the wear and tear on concrete slabs can lead to considerable cost and aggravation for warehouse managers. Traditional concrete slabs are prone to cracking and curling, which gets worse with heavy traffic from forklifts or automated storage and retrieval systems. These repairs are costly and disruptive, particularly for retail businesses that cannot afford lengthy warehouse or distribution center downtime. Even minor cracks in the concrete slab can also damage forklifts and retrieval equipment, resulting in more downtime.

DUCTILCRETE engineered slabs can help lower maintenance costs by up to 75 percent. By drastically reducing the number of control joints and utilizing a system that reduces the potential for curling, DUCTILCRETE engineered slabs remain flat. In this way, the system helps minimize the potential of developing cracks that commonly occur in concrete slabs and the associated wear and tear on forklifts going over uneven slabs.

INCREASE WAREHOUSE CAPACITY

DUCTILCRETE engineered slab systems also provide a cost-effective way to expand warehouse capacity. DUCTILCRETE systems frequently have the ability to reduce the slab profile yet provide higher allowable loads when compared to conventional slab designs. Additionally, since DUCTILCRETE systems have far fewer joints, tenants have greater flexibility in racking and equipment layouts.

These very flat slabs are also ideal for those using a computerized picking system or cantilevered racking systems. They can also be easily adapted to support a wide range of uses, such as food grade, manufacturing, or lab grade facilities.

REDUCE CARBON FOOTPRINT

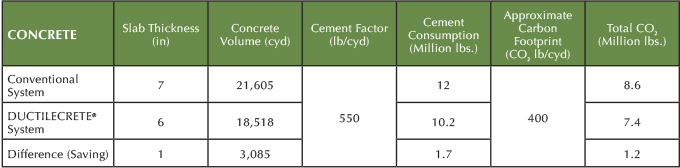

Environmentally-friendly buildings appeal to many of today’s corporations looking to demonstrate their commitment to sustainability. One way to help building tenants reduce their carbon footprint is to move away from using traditional concrete slabs. Concrete slabs contain large amounts of cement, the source of most CO2 emissions associated with concrete use. According to the EPA, for every pound of cement produced, there is approximately 0.9 pounds of CO2 emitted.1 A batch of concrete is made up of roughly 7-15 percent cement, so manufacturing just one cubic yard of concrete results in 400 pounds of CO2 going into the atmosphere.

Since DUCTILCRETE engineered slab systems are typically thinner than traditional concrete slabs, they require considerably less cement. For example, using a DUCTILCRETE system for a 1,000,000-square-foot warehouse could eliminate roughly 1.2 million pounds of CO2 emissions. (See chart)

Sustainability improvements don’t need to be limited to the interior of the warehouse. There are also DUCTILCRETE systems that can replace conventional asphalt paving for warehouse/distribution center parking lots. Black asphalt absorbs light and emits large amounts of heat. This exacerbates the “heat island” effect in urban areas, degrading air quality and causing excess energy use.

Concrete systems, such as the DUCTILCRETE engineered paving system, improve light reflectivity so much that they can actually reduce the amount of lighting required in parking lots and similar structures. In addition, unlike traditional asphalt, which contains volatile organic compounds and oils that can leach into the air and can also contaminate nearby aquifers during rainstorms, DUCTILCRETE engineered paving systems have no such chemicals.

CONCLUSION

There’s little doubt that the e-commerce industry will continue to grow and evolve—and the competition among online retailers will become even more fierce. Warehouse and distribution tenants must squeeze every bit of efficiency out of their operations to stay ahead. This gives proactive industrial brokers an opportunity to stand out by bringing forward innovations that help their tenants tackle big challenges—from being better environmental stewards to reducing operating costs.

References

Lisa J. Hanle, Kamala R. Jayaraman and Joshua S. Smith, CO2 Emissions Profile of the U.S. Cement Industry, www3.epa.gov/ttnchie1/conference/ei13/ghg/hanle.pdf

For More Information

For more information on the DUCTILCRETE engineered paving system, visit product.gcpat.com/ductilcrete.

Modern Contractor Solutions, May 2019

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.