In early 2020, work started on a $230 million renovation for the Footprint Center, home to the NBA’s Phoenix Suns and the WNBA’s Phoenix Mercury. As part of this modernization project, an additional 125 tons of steel had to be added into the existing structure to support new equipment, including a new, 3,500 square foot, HD center-hung video scoreboard that is six times larger than the previous display board, and LED ribbon boards around the arena.

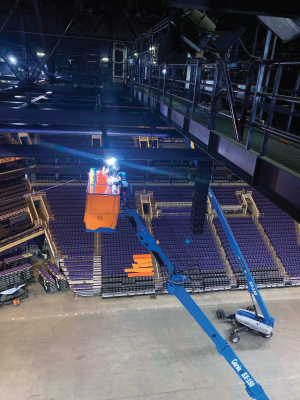

To support this larger video scoreboard, a major component of the renovation, local company FM Steel Construction was hired to perform the structural steel work. FM Steel Construction, in turn, relied on a variety of equipment, including Genie® “Super Booms” to get the job done.

“We had to reinforce all the roof trusses to enable them to support more weight for new display equipment and audio equipment,” explains Michael Mulsow, director of operations for FM Steel Construction, which received a Steel Erectors Association of America (SEAA) “Project of the Year” award for their work on the arena renovations. “The main equipment we used were the 180-foot and 150-foot lifts, but we also utilized all kinds of other machines like scissor lifts, Z®-booms, forklifts, and more throughout the process.”

HIGHEST-REACHING BOOMS

needed to add 125 tons of steel to the arena,

including the framework for a new video screen and

other lighting and sound upgrades as part of a major

renovation project.

Among the equipment used by FM Steel were Genie SX™-180 and SX-150 telescopic boom lifts. The SX-180, the highest-reaching model in the Genie boom lineup, boasts a max working height of 186 feet, a horizontal reach up to 80 feet while the SX-150 features a vertical reach of 152 feet and a horizontal reach of 80 feet. With a 10- foot rotating jib, both the SX-180 and SX-150 offer uncompromising productivity and are well-suited for even the most extreme jobs such as the steel work at the Footprint Center.

“For this project, the reach was important as there are not a lot of machines that will take you that high,” Muslow says. “The best part of these lifts is the fact that you can actually drive them while you’re in the air, which saved us even more time.”

He adds: “The Genie lifts we used were a big part of the project’s success. If we had to access this work from the steel, it would have taken triple the cost and time as well. We would’ve needed to use hanging scaffolding or actual rope climbing equipment, which is extremely costly.”

For More Information:

Since 1966, Genie has been the leading name in the aerials industry. With offices, team members and manufacturing facilities around the globe, Genie lifts and telehandlers can be found enhancing safety and improving productivity on jobsites worldwide. Genie’s ongoing leadership in aerial lifts and material handlers is built on our ability to consistently deliver superior quality for our customers. At Genie, we achieve this quality not by chance, but by design. For more, visit www.genielift.com.

Terex Corporation is a global manufacturer of aerial work platforms and materials processing machinery. The Company designs, builds, and supports products used in construction, maintenance, manufacturing, energy, minerals, and materials management applications. The Company’s products are manufactured in North and South America, Europe, Australia, and Asia, and sold worldwide. The Company engages with customers through all stages of the product lifecycle, from initial specification and financing to parts and service support. For more, www.terex.com.

Modern Contractor Solutions, December 2021

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.