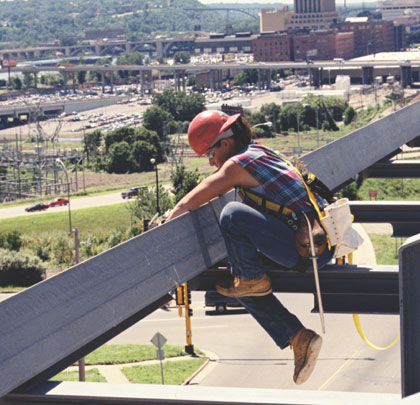

As a construction professional, you’ve likely mastered the basics of fall protection since your first days on the job. Using the right equipment and receiving the right training has probably become instinctive, built into your everyday routine. However, each jobsite has its own unique challenges and requirements, which can leave even the most experienced workers feeling unsure. Below are three common questions Capital Safety’s expert team hears from workers across the country in the construction industry.

What is fall clearance and how do I calculate it?

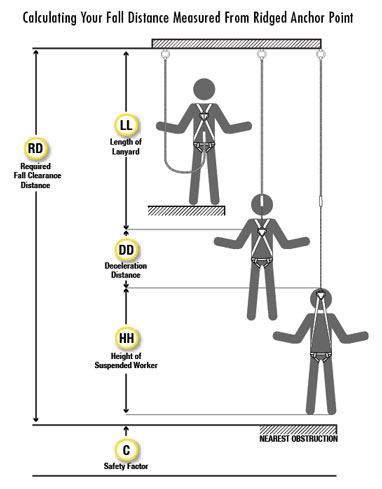

Fall clearance is the minimum distance a worker needs in the event of a fall to avoid striking the ground, or other object below, before the fall is arrested. It’s crucial to understand that fall clearance is more than just the simple measurement from a worker to the nearest obstruction—the correct calculation could mean the difference between serious injury and a safely arrested fall.

Fall clearance is the minimum distance a worker needs in the event of a fall to avoid striking the ground, or other object below, before the fall is arrested. It’s crucial to understand that fall clearance is more than just the simple measurement from a worker to the nearest obstruction—the correct calculation could mean the difference between serious injury and a safely arrested fall.

To calculate fall clearance accurately, there are multiple factors to consider. The proper calculation formula to use for energy absorbing lanyards is the length of the lanyard + the deceleration distance of the energy absorber + the height of the worker + a safety factor. A distance of 1.5 feet is commonly used as a safety factor. If the distance between the anchorage point and the nearest obstruction is less than the calculated fall clearance distance, the fall arrest system cannot effectively protect a worker from the dangers of a fall from height.

For situations in which the anchorage is not directly above the worker, swing fall distance must also be taken into account. Because a swing fall generally lengthens the overall vertical fall distance, clearances must be appropriately adjusted. Additional charts and formulas are also available for other fall protection connecting systems, such as self-retracting lifelines.

What is the difference between OSHA and ANSI?

While both OSHA and ANSI play a significant role in keeping workers safe, their roles are different and should not be confused.

OSHA (Occupational Safety and Health Administration) is a division of the U.S. Department of Labor charged with setting and enforcing safety regulations in the workplace. OSHA also provides training, outreach, education, and assistance for workers in order to facilitate awareness and understanding of such standards. OSHA regulations are governing law and therefore mandatory in nature, requiring all applicable employers and their workers to comply. Those found not in compliance can face serious consequences, including citations and hefty fines.

ANSI (American National Standards Institute) exists to promote and facilitate voluntary consensus standards that are aimed at improving workers’ safety on the job. ANSI standards are intended to serve as recommended guidelines and often go more in-depth than OSHA regulations. However, unlike OSHA regulations, ANSI standards are not mandatory and following them is not required by law. While employers and workers can choose to ignore ANSI standards without facing any monetary penalties, doing so could (and often does) place their workers’ safety in jeopardy.

Even though OSHA and ANSI are separate organizations, safety and health are of paramount consideration for both. In that sense, they are deeply intertwined and should be used together to enhance and strengthen the safety of workers. Those who truly put safety first are known to actively follow all applicable OSHA regulations, as well as ANSI standards.

What should I do if someone falls on the jobsite?

Even with the very best fall protection system in place, it’s still possible for a fall to occur. Don’t risk being unprepared and poorly trained on how to handle the situation if a fall occurs. First and foremost, OSHA regulations require that you have a comprehensive, written rescue plan in place that all workers are trained on and can access at any time. Many equipment manufacturers offer sample rescue plans as a starting point for developing your own.

Once there is a comprehensive plan in place, there are four crucial steps to follow when a fall occurs:

- Respond to the fall. The ANSI Z359 code states that no more than 6 minutes should pass from the time a worker falls to when they are reached. This time limit is put in place to help mitigate the risks of unconsciousness or further injury of a suspended worker. OSHA requires the provision of medical aid to the fallen worker within 4 to 6 minutes.

- Monitor the fallen worker. Continuously communicate with the worker, especially if he or she is suspended for a prolonged period of time. Encourage the fallen worker to move their arms and legs to promote blood flow to the extremities. If the worker describes symptoms of dizziness, fainting, nausea, breathlessness, or experiences low heart rate, low blood pressure or loss of vision, notify emergency medical services immediately, as these are warning signs of a more severe injury.

- Follow the rescue plan. Use the rescue plan to determine safe next steps and have a trained employee rescue the fallen worker. The best rescue plan avoids putting the rescuer in harm’s way.

Transport the worker to a safe area. In most situations, the ground is the safest level, but some jobsites may require transporting the worker to a different area, such as the interior of a building. Once the worker is in a safe area, determine if first aid treatment needs to be administered or if the fallen worker needs to be transported to a hospital.

Fall protection can, at times, seem like a daunting task, but it doesn’t have to be. Proper equipment and ongoing training saves lives and boosts employee morale. If you have additional questions on how to stay safe at height, contact your safety equipment manufacturer for help. ■

About the Author: Craig Firl is the North American technical manager with Capital Safety. He can be reached at cfirl@capitalsafety.com. For more information, call 800.328.6146, or visit www.capitalsafety.com.

[divider]

Modern Contractor Solutions, April 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.