By Dean Marris

The construction industry in the U.S. has reached a critical milestone in its technology transformation. Aggregate suppliers and ready-mix fleet companies are achieving new efficiencies by deploying connected fleet management systems. With recent innovations, a complete 360-degree view into the performance and behavior of an entire construction supply operation is now at your fingertips.

Here are a few advanced technology applications that suppliers are utilizing to enhance visibility and improve productivity in their operations:

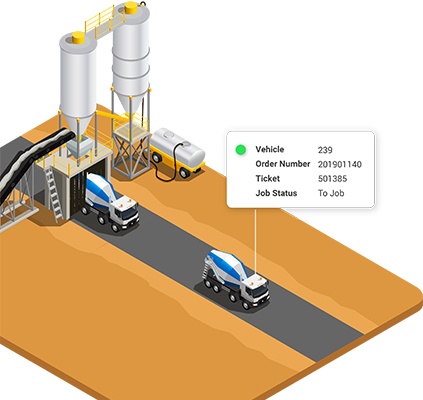

INTEGRATED JOB STATUSING

Every minute counts in ready mix. Fleet operators must deliver perishable concrete exactly when and where it is needed. Cumbersome paper-based ticketing systems and manual processes are, fortunately, methods of the past.

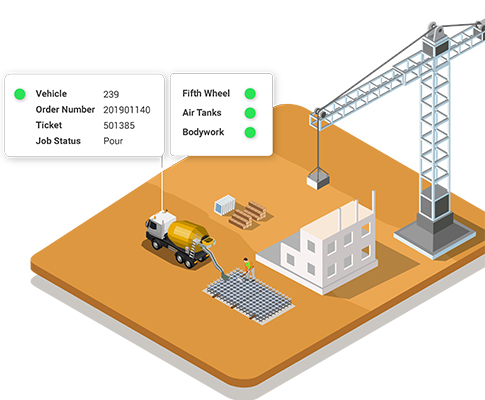

Real-time tracking with integrated job statusing feature allows key personnel in your supply chain to see at any given point in time just how many concrete mixer trucks are ticketed, en route, on site, waiting on site, pouring, and traveling back to their plants.

This automatic operation data and granular workflow view is generated by an Internet of Things (IoT) platform, combined with a complete set of high definition sensors specifically designed for use in a ready mix and aggregate environments.

This comprehensive data also improves customer satisfaction as technology empowers the end-user as well as fleet operators. The contractor receiving concrete has visibility into real-time load delivery times and a new level of confidence in the quality of materials supplied. We provide our customers’ customer with a comprehensive “birth certificate” of concrete, including valuable sensor data about the mix, slump and time to pour. The documentation allows suppliers to verify and prove to contractors that their concrete was delivered on time and according to specification.

IN-CAB MONITORING

In-cab solutions link drivers to vehicles and vehicles to dispatchers. Fleet operators are armed with navigation information, messaging and push-to-talk capabilities, job workflow management tools and real-time driver behavior feedback.

Electronic Logging Devices (ELDs) with integrated construction rulesets captures critical in-cab performance data, such as hours of service for new intrastate safety regulation compliance, GPS location, engine idle times, and ignition on and off time stamps.

Reducing fuel consumption is one of the biggest money savers that in-cab systems provide as excessive jobsite waiting times are costly. Monitoring work time vs. idle time on equipment identifies which vehicles are running outside of defined work parameters and responsible for wasting fuel.

PREVENTIVE MAINTENANCE & DVIRS

Engine diagnostics technology provide real-time engine faults, severity levels and insight into the number of times they have occurred. While ready mix operations primarily involve short trips, there is a mindset that this type of technology is not necessary—it is.

Driver Vehicle Inspection Reports are also helpful. DVIRs are fully customizable pre- and post-trip paperless checklists that identify defects within vehicles. Mechanics can easily see what work needs to be performed before the truck goes back out on the road.

By adhering to a preventive maintenance schedule and adopting technology to identify potential issues, businesses can extend vehicle lifecycles and avoid unnecessary equipment replacement costs. These tools empower your maintenance department to stay on top of any issues that may arise to keep your vehicles on the road and reduce unplanned downtime or loss.

SYSTEM INTEGRATIONS

Many fleet management companies are required to have multiple systems that track different aspects of their business. Streamlining and synchronizing telematics and sensor data with disparate batch and dispatch systems is a major challenge in our industry.

Fleet management platforms need to fully integrate with major ready mix and aggregate dispatch systems and other third-party applications including CRM, billing, reports, and business intelligence tools.

High definition device data and any integrated information are displayed on a single visualization dashboard. Users can easily see cubic yards, contractor jobsite waiting time and ranking of contractor, utilization, total ticketed, trip time, driver cubic yards per man-hour and driver behavior, enabling informed business decisions.

SOLUTION AS A SERVICE

Large ready mix and aggregate suppliers were the first to reap the benefits of advanced fleet management systems. Dispatchers, safety teams, maintenance staff, and plant managers have applied a single-platform approach to gain operational insights, streamline their supply chain, and enhance event resolution.

No matter the size of business, the main objectives for all construction supply companies are the same: to increase the volume of yards per man-hour, decrease operational costs, and ensure the end-to-end quality of concrete delivered.

The barrier for entry to adopt new technology solutions for many companies has been the upfront capital investment required. Many businesses operating with less than 50 trucks have somehow been left out of this technology revolution.

A subscription-based model with pricing for specific à la carte features is now available. A monthly fee for a complete customized solution includes hardware (sensors, black box unit, in-cab mobile devices), software, and operating system upgrades. This “leasing” option levels the playing field by allowing companies of any size to easily adopt a connected solution and enables the flexibility to expand features as business needs grow.

CLOSING THOUGHT

It is now easier than ever to take advantage of the new digital transformation in the ready-mix industry. By collecting data from disparate sources and deploying a single integrated platform, you can efficiently transform your operation and take it to the next level.

About the author

Dean Marris is co-founder and EVP of Coretex, a leading compliance and fleet management solution provider. Coretex’s cloud-based visualization platform helps construction customers worldwide turn rich data into automated business intelligence. For more, visit www.coretex.com.

Modern Contractor Solutions, October 2019

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.