By Troy Dahlin

The world is moving into the post-COVID era, and the economy continues to rebound. As a result, construction projects are kicking into high gear.

Couple that with the all-time high prices of materials, and companies need a technology solution that allows them to optimize their procurement processes and make wise use of their precious and increasingly expensive resources.

The good news is there is a readily available technology that will allow them to do so: drones.

DRONE TECHNOLOGY

The adoption of drone technology has increased in heavy construction in recent years. Because drone systems are easier to use than ever before, they enable generalists to take advantage of the technology and deploy them to save time and money on critical projects.

These systems provide increasingly accurate data. As a result, they offer a cost-effective way to use technology to tackle long-standing needs, such as safely capturing the accurate and robust data needed to make real-time decisions that can make or break a project’s bottom line.

According to the Federal Aviation Administration (FAA), there are more than 1.7 million drones, or unmanned aerial vehicles (UAVs). Additionally, 203,000 remote pilots are registered with the federal agency, numbers likely only to rise in the coming years.

Recent data from The Civil Quarterly (TCQ), a quarterly research report on the current business health of contractors from Dodge Data & Analytics, revealed that the heavy civil sector has widely adopted many advanced tools and digital processes. For example, more than half of contractors said they used drones and ruggedized tablets.

Heavy construction contractors need solutions that simplify their workflow and allow them to leverage vast amounts of data to make actionable decisions. Here are a few new ways drones are shaping commercial projects.

1. DRONES CAPTURE ACCURATE DATA CONTRACTORS NEED TO MAKE INFORMED DECISIONS

Drones capture more data in a 20-minute flight without disrupting jobsite operations than a team can capture during a week of traditional terrestrial measuring. This data leads to improved client visualization as a drone’s detailed images show overall site progress against the design.

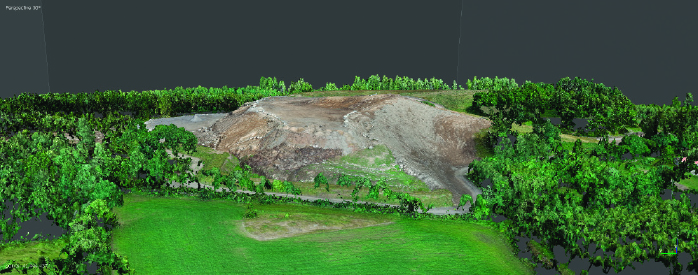

Processing these images—known as orthomosaic images—as three-dimensional points on the ground can be combined with three-dimensional points from other collection sources. Those points can be used in computer-aided design (CAD) to create three-dimensional surfaces, contour lines, surface features, three-dimensional models, site progressions documentation, and volumetrics for earthwork calculations.

Because the data is dense, rich and accurate, it enables more detailed analysis, translating into quicker and more complete decision-making at the project management level.

2. DRONES HELP TEAMS SAVE TIME AND MONEY

In heavy construction, much of the focus has been to use drones to quantify earthwork volumes. For example, contractors often use drone technology to help with their pre-bid analysis.

By ensuring they know the correct quantities needed, they can create optimal designs and implement efficient haul plans.

Then, throughout the construction process, contractors can use drones to track earthwork volumes. With this information in hand, they can knowledgeably provide feedback on completed tasks and analyze the work remaining to inform project plans that allow for faster replanning cycles.

Additionally, teams should use this technology to monitor their jobsites to gather data for progress reporting and stockpile management. This information should drive lean procurement management, ensuring teams have on-site the materials they need when they need it and that it is stored in the correct location to keep it safe and secure until the proper time.

Similarly, operators should deploy drones to observe their on-site equipment to ensure it is appropriately utilized and verify a location’s conditions are safe and comply with all applicable regulations. Confirming this information and acting quickly when a problem arises will save the time, expense, and hassle of correcting a problem.

This provides a feedback loop for the field to the office and back again to merge drone data with design, as-built, and on-site progress updates captured with photos, notes, and machine tracks.

Contractors can also use drones to validate and hand over the asset to the owner, helping reduce the time needed with manual approaches. In addition, taking this approach ensures the final product is constructed within specification, eliminating the need for costly fixes.

3. DRONES GO WHERE NO TEAMS CAN, LEADING TO INCREASED JOBSITE SAFETY

While drones’ most significant upside may be their fast and flexible data collection, the technology delivers reduced worker costs, enhanced jobsite safety, and faster surveying and construction time than traditional data capture techniques.

Drones enable heavy construction contractors to safely, efficiently, and accurately capture data from hard-to-reach, potentially hazardous or otherwise inaccessible locations that would be too risky or expensive to capture traditionally. They are instrumental in urban environments or on heavily canopied construction sites.

They permit safe automated data capture to create measurable 3D models and powerful 2D visuals to incorporate into workflows. Drone deliverables enable contractors to bring more eyes to a problem and do this within the safety of an office.

Despite their proliferation, many contractors are unaware of the profound benefits drones bring to the modern jobsite. Many construction companies initially deployed drones thinking they would have them on hand at a site at all times, but they work best when they are not viewed as a tool to be used 24/7.

Over time, companies’ plans for drones evolved into having a dedicated team of professionals who travel from site to site where their drone operating services are needed.

CLOSING THOUGHT

Solutions today make jobsites safer while driving cost savings; contractors must view today’s technology as the professional partner that will help them save time and money. When implemented correctly, technology provides the most potent tool in contractors’ toolboxes.

For more information:

Troy Dahlin is vice president, heavy construction segment, US/CAN of Leica Geosystems, part of Hexagon. For more, visit www.leica-geosystems.com.

Modern Contractor Solutions, July 2021

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.