Danfoss Power Solutions’ Editron division has delivered its first eHydraulic Power Module to SANY for the electrification of a 200-tonne lattice-boom crawler crane. The eHydraulic system integrates a Danfoss Editron synchronous reluctance assisted permanent magnet motor with a Danfoss variable displacement axial piston pump to maximize performance and efficiency. SANY launched the fully electric battery-operated crane earlier this year.

Construction machinery worldwide emits an estimated 400 million tons of carbon dioxide per year, according to IDTechEx. With the scale of global construction activity set to increase significantly in the decades to come, decarbonizing heavy-duty machinery is vital to curbing greenhouse gas emissions. Leading crane manufacturer SANY is supporting these efforts and helping its customers achieve zero-emission construction sites through the electrification of its lattice- and telescopic-boom crawler cranes.

HIGHER CAPACITIES

SANY is working to develop fully electric versions of its higher capacity crawler cranes, having previously electrified its lower capacity models. Danfoss supplies Editron motors and D1P pumps for SANY’s 80- to 150-tonne cranes. For its 200-tonne platform, SANY opted for an integrated Danfoss eHydraulic Power Module to power the traction and work function systems.

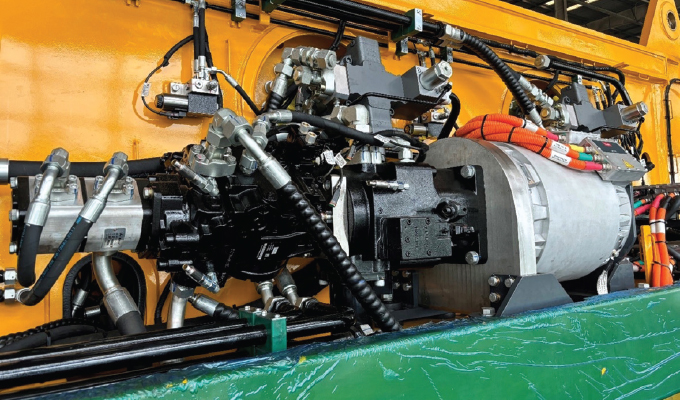

Comprising an Editron PMI375-T1100 motor and D1P 260-cc pump, the system is optimized to deliver peak performance and maximize hydraulic system efficiency, extending machine runtime on a single charge. The full hydraulics system also includes a Danfoss Series 90 pump and PVG 128 valve.

SANY realized additional benefits with the Danfoss eHydraulic Power Module, including a compact package with mechanical advantages, simple installation, and high reliability. Supplying the electric motor and hydraulic pump as an integrated package eliminates the risk of noise, vibration, and component damage that can arise when using a flexible coupling to join the components.

CE marks and the Danfoss global service network were also key reasons SANY chose to partner with Danfoss. “Building a solution for SANY’s high-capacity platform with the Danfoss integrated eHydraulic Power Module marks a milestone,” says Roy Chen, president, Editron division, Danfoss Power Solutions. “eHydraulics represents the future. Together with our Controls division, we have designed a system combining our D1P pump and Editron motor while tuning controls algorithms to maximize efficiency. We look forward to our continued collaboration with SANY and supporting their green journey.”

“Conventional hydraulics still plays a role in the electrification of heavy machinery, particularly machines of this size,” says Henrik Jørgensen, president, controls division, Danfoss Power Solutions. “By integrating Danfoss’ advanced hydraulic solutions and electrification technology, we are empowering a smooth transition to more sustainable operations. Leveraging our eHydraulic solutions and our application know-how, we aspire to be the partner of choice for visionary OEMs like SANY.”

about the author

Roy Chen is president, Editron division, Danfoss Power Solutions. Danfoss engineers solutions that increase machine productivity, lower energy consumption, enable electrification, and reduce emissions. With innovative engineering that dates back to 1933, Danfoss is family-owned and employs over 39,000 people, creating long-term value for its customers in more than 100 countries with a global footprint of around 100 factories. For more about Danfoss solutions for electrification, visit www.danfoss.com/editron.