There is no straight forward, simple definition of what sustainability means to the construction industry. In fact, there are few tools or even metrics available that can help decision-makers select one construction material over another in relation to sustainability. There is a simple reason for that: The sustainability of concrete—the most widely used material in the world—is still a difficult concept to quantify.

DEFINING SUSTAINABILITY

According to the U.S. Environmental Protection Agency, sustainability is based on a simple principle: Everything we need for our survival and well-being depends, either directly or indirectly, on our natural environment. Through sustainability efforts, we can ensure that we have, and will continue to have, the water, material, and resources needed to protect human health and the environment.

The sustainability of a construction material is affected by at least two factors: the amount of non-renewable materials that enter into its manufacturing and its lifespan before it has to be replaced and manufactured again. The Concrete Joint Sustainability Initiative states that “to date, most sustainability or green voluntary certification programs attempting to qualify sustainable materials have focused primarily on energy, material, and water conservation; indoor environmental quality; and site selection and development.” While these are all important aspects of sustainable building design and construction, lifecycle does not appear to be an integral part of that definition.

GREENER SOLUTION

Is it possible to produce a “green” concrete? Not unless a new materials chemistry is developed that would yield mechanical properties similar to the “liquid stone” while tapping less into non-renewable resources. According to Ken Vallens, vice president of product development and engineering sales at CTS Manufacturing Corp., one “greener” concrete that is available is calcium sulfoaluminate (CSA) cement.

“This rapid-setting cement requires burning mixtures of limestone, bauxite, and gypsum at lower temperatures than portland cement,” says Vallens. “It’s approximately 2700 degrees F for portland cement versus 2250 degrees F for CSA cement. This lower burning temperature reduces the amount of energy and carbon dioxide emissions associated with portland cement production.”

Vallens explains that CSA cement also requires less limestone, the primary source of carbon dioxide released during the chemical sintering process. CSA clinker is also easier to grind, which reduces the energy needed during the milling process. Consequently, CSA cement can play a significant role in improving the sustainability of construction materials by simply reducing the quantity of non-renewable resources used during manufacturing. The use of resources is just one part of the equation. Durability—or lifecycle—is the other component of sustainability.

SUSTAINABLE DEFINITION

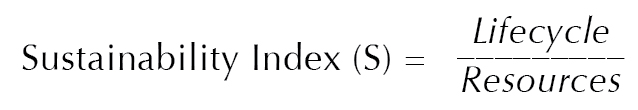

When selecting a building material (e.g. asphalt vs. portland concrete vs. CSA concrete) sustainability should be easily quantifiable. One method for assessing the sustainability of construction material could be to divide its lifecycle by the amount of non-renewable resources required in the manufacturing process.

Using this method, a “Sustainability Index” would look like this:

Lifecycle is the durability of concrete, in years. It is linked to fatigue life and other material properties, such as shrinkage, cracking, and porosity. Resources refers to the quantity of non-renewable resources used in concrete manufacturing (such as, but not limited to, carbon footprint). The Sustainability Index can have the unit of [yd3*years/ton-CO2].

THE LIFECYCLE OF CONCRETE

This simple, straightforward index can help rate the sustainability of various materials and mix designs and help decision-makers choose materials consistent with stated sustainability goals.

“The Sustainability Index brings lifecycle into the equation: a greater lifecycle decreases the burden on our resources,” says Vallens. “A 100-year pavement would have five-times the Sustainability Index of a 20-year pavement, all other parameters being equal. At equal lifecycle, a mix design with half the carbon footprint would have twice the sustainability. It is a simple concept tying economic decisions to materials properties.”

The concept also highlights that the sustainability of concrete is, above all, a materials property: lower shrinkage and lower porosity increase lifecycle, for example. Doubling the lifecycle while halving the carbon footprint, quadruples the Sustainability Index. Using this approach, the sustainability of concrete is not such a nebulous concept—its basic definition becomes “the lifecycle of the material per unit of non-renewable resources.”

With this definition of sustainability for the concrete industry, decision makers now have a tool allowing them to choose between materials of different lifecycles made with different resources. Choosing a sustainable building material should be matter of figures and numbers.

COST CONSIDERATIONS

Cost is a significant factor in the selection of sustainable building materials. On a pound-for-pound basis, CSA cement is approximately three times more expensive than portland cement, or 1.2 times more expensive than portland cement accelerated with organic additives. This differential is thought-provoking for engineers and specifiers responsible for selecting a repair material: Does it make more sense to select a cheaper, less durable material when the longer-lasting alternative is more expensive?

“As a matter of accountability to the public who generally pays for these repairs, the long-term benefit of a longer lasting pavement outweighs the short-term impact on a budget,” says Vallens. “A cheaper material that needs to be replaced in 20 years simply shifts the burden to our children. Pavement rehabilitation must make lifecycle its first priority over purchase price.”

A cheaper material that needs to be replaced in 20 years simply shifts the burden to our children. Pavement rehabilitation must make lifecycle its first priority over purchase price.

The Sustainability Index now becomes an important tool. It helps engineers and specifiers make decisions on cost and lifecycle considerations and environmental impact without being overly complex.

The industry must educate itself on the advantages of the technology for CSA to become widely used. There is always inertia in specifying a material that deviates from standards, especially if those standards were established in the 19th century. When engineers have a choice of materials, they need a tool to differentiate between them. The Sustainability Index are one of many valuable tools that help decision-makers make informed, sustainable materials choices in tight fiscal times.

The construction industry should look at calcium sulfoaluminate cement with a fresh eye because of its impact on sustainable development and the improvement of our infrastructure.

■ ■ ■

[divider]

For More InformationCTS Cement Manufacturing Corporation manufactures Rapid http://www.mcsmag.com/site/wp-admin/edit.phpSet® professional-grade cement products for concrete repairs and new construction projects. For more information, visit www.ctscement.com.

Modern Contractor Solutions, MAY 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions Magazine!