In the 2010s, the 16th Street Mall in Denver had a problem. Deteriorating conditions in the granite paver system and inadequate subsurface drainage were resulting in frequent disruptions to the transit system. Maintenance costs related to this deterioration had ballooned to $1M annually. Spiraling costs were creating an unsustainable situation for local stakeholders, and decisions had to be made about the future of the Mall.

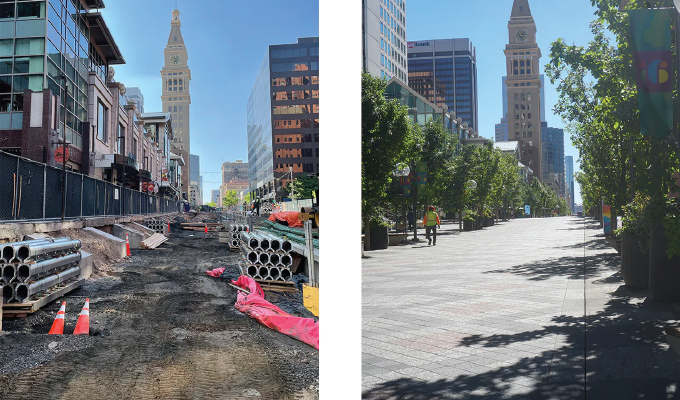

The 16th Street Mall has been a fixture of Downtown Denver since its construction in 1982. It serves as an economic engine for the area, drawing locals and tourists alike. Based on its historic, economic, and civic importance, the decision was made to improve surface drainage and secure the sustainable future of the 16th Street Mall. This led to the creation of the 16th Street Mall Project, which called for the excavation of the mall to re-grade the land, replace the pavers, and upgrade the underground drainage system. Global Drain Technologies was selected to supply the stainless steel drainage required to achieve this generational project.

SUPPLYING STORM WATER DRAINAGE

Civic spaces like the 16th Street Mall require storm water drainage, which drains excess rainwater or snowmelt from hard surfaces like roads, parking lots, transitways, and pedestrian walkways and diverts it through storm sewers away from dense urban areas.

If rainwater is not properly drained, it eventually seeps down between the pavers or under the concrete and slowly erodes the stone or sand base. This can result in the formation of depressions or potholes. These depressions then collect water leading to even more erosion. This vicious cycle can result in ever increasing maintenance costs for civic spaces with inadequate storm water drainage.

The 16th Street Mall Project features an innovative drainage design that moves away from traditional curbside inlets to nearly invisible slot drains that blend beauty and functionality.

FLOOD PREVENTION

For the 16th Street Mall Project, Global Drain Technologies deployed its 11,000 Series Slot Drain System, which is reserved for large civil projects or spaces that will see heavy industrial use.

Slot Drain Systems are less prone to blockages than traditional area drains. In an area drain system, water is diverted toward multiple point drains or openings within a large paved area. This design requires that complex slopes be incorporated during the installation of the paver system to ensure water reaches the drains. If one of the drain openings becomes blocked, then the entire area it serves cannot drain. A Slot Drain spreads out storm water collection over the entire length of the drain, requiring less complex slopes in the paver system which helps to prevent blockages.

The linear design of a Slot Drain System also presents advantages in surface drainage capacity. Surface drainage for a Slot Drain System is calculated by taking the entire length of the installed drain and multiplying it by the amount of water each section of the drain can accept in a minute. This is also known as the drain’s intake discharge.

Engineers at Global Drain Technologies were able to plan for and deliver drainage that accounted for extreme rainfall events, including a “once in a hundred-year event” as stipulated by project managers. The 16th Street Mall’s storm water drainage system was delivered with a maximum surface drainage of over 70,000 GPM.

CLEANING & MAINTENANCE

The 11,000 Series Slot Drain System features a pre-sloped stainless steel design, which makes the drain body effectively self-cleaning. The 11,000 series also features a tapered throat extending above the drain body for surface drainage.

The tapered throat is engineered to prevent the accumulation of ice and snow, a requirement of the Mall’s project management team. “We tested and iterated multiple designs,” says Chad Kaatz, VP of engineering and product management at Global Drain Technologies. “The final product allowed ice and snow to fall into the drain body rather than remaining in the tapered throat.”

HEEL PROOF & ADA DESIGN

The 16th Street Mall Project specified heel-proof and ADA compliant requirements for the supplied storm water drainage. Heel-proof drains are designed with narrow openings to prevent high heels or other small items from becoming trapped in the drain. ADA compliance requires that drains have openings no larger than 0.5-inch perpendicular to the direction of travel. Slot Drain Systems like the 11,000 Series fit flush to the surrounding paver system. This allows wheelchairs and other mobility aids to operate freely without encountering obstructions.

STAGED TIMELINE

The 16th Street Mall Project laid out an ambitious phased timeline. The first phase called for the relocation of utilities, including electric, gas, telecom, storm, and sanitary sewer. This phase was planned to take 13-14 months and broke ground in April of 2022. However, like many similar projects, unforeseen challenges, such as buried historic utilities and supply chain issues, caused delays.

Global Drain Technologies worked closely with PCL on this project to ensure on-time delivery of the Slot Drain Systems matched the realities of the project on the ground. The phased delivery approach began with the first drain delivery in November of 2022 and ended with the final delivery in February of 2025.

Clear communication ensured the smooth progress of the project regardless of operational delays. Material was made to order and delivered just in time to the project to prevent early or late material deliveries that could lead to delays or unacceptable staging of materials. The sales, engineering, manufacturing, shipping, and service staff all worked together to ensure this went off without a hitch.

As landscape and civic design continue to evolve, the future of drainage is to seamlessly integrate with the aesthetic of public spaces like the 16th Street Mall. The goal at Global Drain Technologies is to blend form and function.

for more information

Global Drain Technologies (GDT) is a leader in manufacturing drainage products and systems, providing innovative solutions tailored to industry-specific needs. GDT is committed to providing industry-leading service, support, and engineering. For more, visit www.globaldraintech.com.