As cities everywhere emerge from the global pandemic, New York is betting big on the return of the daily commute. With a $12 billion price tag, the long-awaited East Side Access project is giving the busiest commuter rail system in the United States a major upgrade.

At present, commuters traveling into New York City on the Long Island Rail Road arrive at Penn Station, on Manhattan’s West Side—often overshooting their actual destinations on the East Side. Many Long Islanders can still make it to work on public transit in an hour or less. But workers living out on the farther reaches of “the Island” may need 2 hours— or even 3—to reach their destination.

With the advent of East Side Access, help is on the way. By adding direct train service from Long Island to East Manhattan, the project will provide faster commutes, fewer delays, greater reliability, and more options for Long Island residents.

East Side Access is the largest infrastructure project in the 57-year history of the Metropolitan Transportation Authority. Teams have carved out 8 miles of new tunnels beneath the East River, excavating more than 2 million cubic yards of rock, soil, and muck. Workers have laid more than 40.5 miles of new track. Construction required more than 1 million cubic yards of concrete and 90,000 tons of steel.

NEW JEWEL IN THE CROWN

The public face of East Side Access is a brand-new terminal for the LIRR, built directly underneath Grand Central Terminal in Manhattan. The 350,000-square-foot concourse will include 25 retail storefronts, Wi-Fi and cell service, and digital signage with real-time train information. Seventeen high-rise escalators, the longest in the New York City transit system and covering 182 feet, will move commuters between the concourse and mezzanine. The mezzanine leads to upper and lower train levels, for a total of four new platforms and eight new tracks.

Long Islanders are not the only commuters to benefit from this massive investment in public transit. For residents of Queens (one of New York’s five boroughs), the new station could shorten some trips by as much as 40 minutes. Congestion at busy Penn Station is expected to ease. At the same time, the LIRR’s capacity is expected to rise by over 40%.

“As the first modern train terminal to be built in more than a half century, the East Side Access will expand rail service, cut down on travel times into East Manhattan from Queens and reduce crowding,’’ New York Governor Kathy Hochul says. “This is yet another example of New York leading the way as we recover from the pandemic.”

AN UNSEEN WORLD

The new concourse is all that most New Yorkers will ever see of East Side Access. But the project required work on less glamorous forms of infrastructure as well. Major updates were required at Harold Interlocking in Queens, to coordinate the new East Side Access routes with the operations of Amtrak. Crews installed 97 new track switches, five new steel railroad bridges, and 295 poles for Amtrak’s overhead wires.

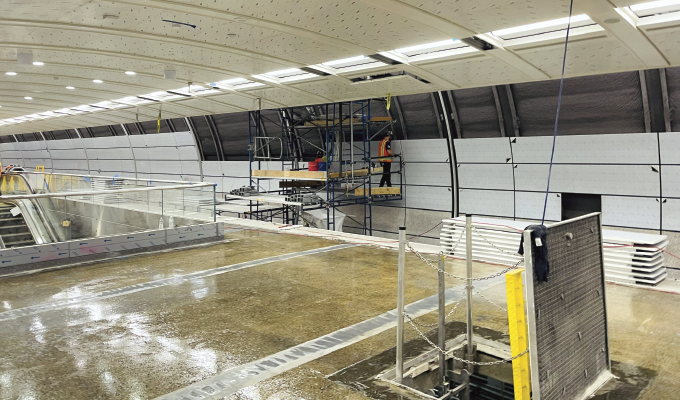

Beneath the streets of Manhattan, the vast new spaces of “Grand Central Terminal Caverns” will house the “guts” of the new LIRR terminal. Two completely new caverns were constructed, each measuring 1,143 feet in length. Two existing caverns were fitted out with 830 precast beams, 844 precast panels, 694 precast walls, and 370 precast platforms.

Workers linked the caverns and tunnels with 130,000 feet of track, 32 turnouts, 52 switches, and 35,000 cubic yards of track bed concrete. Power is supplied by 800,000 feet of underground raceways, 7,000 light fixtures, seven power stations, and two off-track facilities.

SAFETY FIRST

New Yorkers who have lived through 9/11 or Superstorm Sandy are aware of the need for safety planning in public projects of this scale. Amid all the tunnels and junctions for electrical and plumbing fixtures, the new terminal features 53 fire-rated floor doors manufactured by BILCO. The doors range in size from 30 inches x 30 inches to 42 x 60, one of the largest manufactured by the specialty access company.

Fire-rated floor doors are often found in public buildings, dormitories, office buildings, and exit stairwells. BILCO’s fire-rated doors maintain the fire rating of a 2-hour floor ceiling assembly between building floors.

The door hardware and sealants used in each fire-rated floor door are specially selected to maintain the fire rating. Fire-rated doors are provided with a self-closing device and an intumescent fireproof coating on the underside. When a fire breaks out, the closing device is triggered by the heat and closes the door to ensure fire protection. The fireproof coating on the underside of the door then expands and seals the door opening to prevent the spread of fire to the next floor. BILCO’s doors are UL-listed and include a pan cover designed to accept flooring materials for concealed access.

The MTA frequently relies on BILCO to supply doors for their construction projects. Fontana Metal Sales provided the doors for the project. “It’s a product that the MTA knows and it’s easiest to purchase the known product,’’ says Jason Benfield of the civil engineering team working on the project, Tutor Perini. “It’s easier to get something approved when it’s a product that is known to work in these applications.”

CLOSING THOUGHT

The Long Island Rail Road was founded in 1834—making it 52 years older than the Statue of Liberty. At that time, the population of Long Island numbered around 37,000. Today it exceeds 2.8 million. East Side Access marks the LIRR’s first expansion in over 100 years.

For long-suffering Long Island commuters, the project will provide welcome relief. “This smart, transit-oriented development will help spur economic growth, provide better connections to Metro-North Railroad, and lead to reduced automobile traffic and improved air quality in the region,’’ MTA Acting Chair and CEO Janno Lieber says.

About the Authors:

Thomas Renner and Katherine Bonamo write about construction, engineering, architecture, and other trade industry topics for publications throughout the United States.

Modern Contractor Solutions, July 2022

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.