How can you expand your business in the current economic climate without taking a serious look at productivity and bottom line expenses? That was the challenge facing Applied Building Technologies, Inc. (ABTI) of Maryland in 2012. With a fast-growing customer base, the company had the opportunity to grow, but the high cost of doing business and complex fleet operations were impeding their efforts.

STAYING ON TRACK

ABTI operates two divisions—one focused on cleaning industrial HVAC systems and commercial kitchen exhausts, and another dedicated to energy management. With a fleet of eight vans and a staff of 18 service people, ABTI serves organizations throughout the mid-Atlantic.

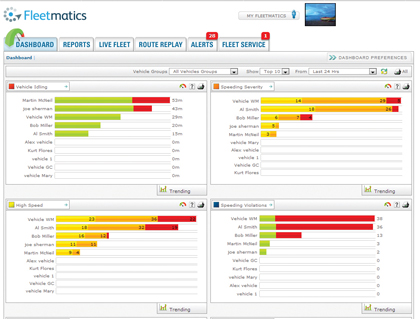

In the last 4 years ABTI doubled its size, but with that came increased expenses and operating costs. As the company looked to continue its growth, it identified several challenges, including skyrocketing fuel costs, high insurance premiums, and reckless driver behavior. Recognizing the need to gain greater control of its expensive fleet operations, ABTI president Anne Levine implemented GPS Fleet Tracking from Fleetmatics.

CURBING RECKLESS BEHAVIOR

Because the company’s service personnel use hazardous chemicals in the course of their jobs and often work in dangerous areas, most insurance companies are reluctant to provide coverage. As a result, Applied Building Technologies must go through a high-risk insurance company and carry an expensive policy.

Ensuring worker safety and limiting claims against workers’ compensation insurance has always been of paramount importance, even more so after two claims were filed in 1 year. Yet the company’s drivers were frequently speeding and driving recklessly. “One time one of our vans was clocked at 90 mph, and these are vehicles that are carrying heavy equipment,” says Levine.

The company couldn’t afford an accident because filing one more claim could send the insurance premium through the roof. “It became even more important to find a way to get a handle on the issue of speeding before the cost of doing business forced us to close the doors,” continues Levine.

The final straw was when one of ABTI’s employees stole one of the vans. According to Levine, the initial driving force for implementing GPS tracking was simply to monitor or locate the vans. Almost immediately, however, the tracking units helped her get speeding and reckless driving under control. When first installed, Levine received 2 to 3 notifications per day about speeding and was able to immediately contact the drivers. She was also able to implement and enforce a policy that dramatically reduced the number of incidents.

DECREASED CONSUMPTION

One of the largest regular expenses for this growing company is fuel. “Our business is a service business and revolves around traveling to and from jobs, so being able to manage all aspects of our fleet from gas usage to real-time locations has become vitally important to our growth,” explains Levine.

With speeding no longer an issue for their heavily-weighted trucks, the company was not only able to save in fuel costs, but also get a better handle on idling by using fleet tracking data to create a report that can easily be exported into Excel for analysis.

As a result, Levine discovered that they were wasting $41 in fuel per week. She now shares the numbers with her crews in staff meetings and started a contest to reward the crew that reduced their idling by the greatest amount. It wasn’t long before she saw real results. “Idling has gone down tremendously, and we’re saving about $20 per week. That’s significant for a small company that’s trying to grow,” continues Levine.

GAINING A VIEW

On top of that, Levine has gained peace of mind from knowing the location of all ABTI’s vans. This is important considering that some of the vans carry up to a hundred filters that cost about $50 each.

According to Levine, at one point, ABTI had an employee who had stolen filters and sold them to a scrap yard for personal profit. Using GPS fleet tracking, Levine was able to enter the location of the local scrap yards into the system and now receives alerts if any of the vehicles travel in the vicinity.

SLASHING PAYROLL COSTS

Another positive side effect of utilizing fleet tracking has been its impact on the payroll process. Levine once spent a considerable amount of time reviewing timecards submitted by service crews. Now she can quickly compare timecards with more accurate tracking data, spending 3 less hours managing payroll and saving the company about $230 per week.

MOVING FORWARD

Levine looks forward to saving even more by taking advantage of additional fleet tracking functionality, such as the integrated fuel card, which allows the company to capitalize on discounts at certain fuel stations.

She also plans to use fleet tracking to assist with regular vehicle maintenance. To date, ABTI has relied on drivers to report when vehicle maintenance or repair is needed. “You waste a lot of time managing a fleet using paper and a calendar,” Levine explains. “Using this new technology, we’ll save both time and money by keeping our vans running better.”

According to Levine, GPS tracking tools have contributed to the company’s overall growth plan, as an integral part of their new technology infrastructure that will make it possible for them to continue to expand. Thanks to fleet tracking, she has a better handle on the business, more effective control of costs and liabilities, and more confidence in the company’s growth potential. Levine sees nothing but a wide-open road of opportunity ahead for ABTI. ■

About The Author:

Derek Breedlove is a regional accounts manager at Fleetmatics, a leading global provider of fleet management solutions delivered as a software-as-a-service (SaaS) to more than 20,000 customers with more than 417,000 vehicle subscriptions worldwide. He can be reached at 704.716.7645, or visit www.fleetmatics.com.

_________________________________________________________________________

Modern Contractor Solutions, January 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.

Better Fleet Management Helps a Business Grow With Confidence