Construction is approaching its next era of innovation, fueled by the demands of a rapidly growing population and the need for sustainable infrastructure as well as the pressing challenges caused by inflation, supply chain disruptions, and geopolitical turmoil. Construction leaders are therefore increasingly challenged to meet expectations to deliver on time and on budget. These factors are reshaping the building ecosystem, prompting a shift toward data-driven solutions and demanding swift and decisive action from construction firms.

The solutions to these challenges are becoming increasingly difficult to find using traditional approaches such as training and hiring external consultants. Forward-thinking leaders within the construction industry are turning toward autonomous technologies to transform operations and improve productivity, sustainability, supply chain efficiency, and more.

To gauge this changing landscape, Hexagon conducted its Autonomous Construction Tech Outlook. Surveying more than 1,000 technology decision-makers from commercial general contracting firms in Australia, the UK, and North America, this study shed light on the industry challenges, the short- and long-term priorities, and the adoption of autonomous technology in the building construction industry today. The research demonstrated that technology is key to overcoming construction firms’ most pressing business challenges, including managing supply chain and materials, inefficiencies and waste, and communication. The survey also provided valuable insights into the disconnect between businesses identifying their key pain points and priorities and the subsequent adoption of the best autonomous technology to help address them.

EMBRACING AUTONOMOUS TECH

Autonomy has moved out of the emerging technology space in commercial construction into widespread adoption. The research found that 84% of firms are using autonomy in some part of their operations. These companies reported benefits from within their operations across many challenges and priorities, including improved sustainability, less waste, better supply chain mapping, better safety compliance, and faster decision making. With autonomous tech, the leverage gap closes between the data created during a project’s lifecycle and the data used to produce actionable insights.

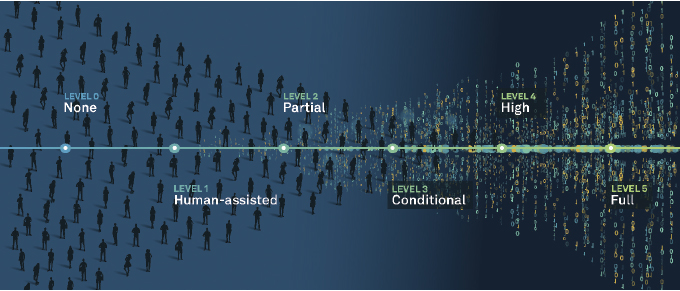

The construction industry’s adoption of autonomous technology includes software and tools, self-driving construction vehicles, and robotics. Today, the most popular application of automation is for project management. It is important to note that there are different levels of automation, from limited or partial to full autonomy. Thirty percent of the companies surveyed who had introduced autonomous solutions had implemented autonomous technologies requiring no human interaction, or full autonomy, freeing up key resources and enabling people to spend more time on complex tasks.

For example, AECOM Tishman, a subsidiary of AECOM, is focused on three main challenges during large-scale and complex projects: monitoring progress, identifying deviations, and handling ongoing design changes during construction. In an effort to proactively address issues before they occur, AECOM Tishman aims to capture discrepancies between field installations and BIM. To achieve this, the team implemented autonomous inspection analysis and progress tracking as well as custom reports tailored to their needs. The outcome was a blend of meaningful data autonomously visualized in an accessible and digestible way, including weekly progress dashboards, labor productivity projection analysis, forecasting progress per trade labor data, and impact analysis with future-looking clash detection. As a result, AECOM Tishman identified 112 critical forward-looking clashes within two months, and weekly progress reporting led to an improved ability to flag issues and adjust work in the field, minimizing production waste and costs.

BRIDGING THE GAP

Although commitment to autonomous tech is forecasted to grow, with 79% of firms planning to invest an average of $7.1M in autonomous solutions within the next three years, the survey revealed a disconnect. Companies understand the benefits of autonomous technologies but often do not apply them to advance their business goals. For instance, among survey respondents who stated that improving supply chain management is a top priority in the next 12-18 months, only 28% reported their companies had invested in autonomous monitoring technology, one of the top reported technologies that aid in this area. Additionally, 37% of respondents using fully autonomous robotics report that it drives sustainability benefits, the leading priority in the next three to five years, yet only 17% of firms are investing in this type of technology now.

These disparities represent a significant opportunity within the industry. Identifying the best autonomous technology solutions through planning and investing strategically will help firms address specific priorities and pain points.

BEYOND REPUTATION

Despite its reputation for being resistant to change, the construction industry has identified technology investment as key to solving its most pressing business challenges. In fact, 60% of respondents believe autonomy will have a significant impact on market competitiveness. With 84% of respondents reporting to have adopted some form of autonomous technology already, those companies who do not innovate in the same way risk lagging as the technologies and the businesses who apply them continue to advance, gaining a competitive edge over their less tech-savvy counterparts.

CLOSING THOUGHT

The key now is to help the industry leverage this technology to target key pain points and ensure lasting and scalable results across the board. Just like the industry’s transition from manual to power tools, or paper to digitization, autonomous technology is a transformation that will define the next era of construction. Changing the perception of autonomous technology to encourage understanding of their applications and how they can be applied directly to specific business priorities will help remove obstacles to adoption and ensure that firms stay competitive in an ever-evolving market landscape.

About the Author:

Taylor Cupp is senior manager of building solutions with Hexagon, the global leader in digital reality solutions, combining sensor, software and autonomous technologies. Hexagon puts data to work to boost efficiency, productivity, quality, and safety across industrial, manufacturing, infrastructure, public sector, and mobility applications. For more, visit hexagon.com and follow us @HexagonAB. For a copy of Hexagon’s Autonomous Construction Tech Outlook, go to hexagon.com/contechreport.

Modern Contractor Solutions, July 2023

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.