Reminder of the Risks Associated with Ultra Low Sulfur Diesel During Refueling

Construction season is in full swing throughout the country, so the Association of Equipment Manufacturers (AEM) wants to remind contractors of the related risks associated with Ultra Low Sulfur Diesel (ULSD) during refueling.

Since 2006, diesel fuel produced or imported into the U.S. has been required to be ULSD fuel. ULSD is replacing Low Sulfur Diesel (LSD) fuel, which contains a maximum of 500 ppm sulfur.

Used in combination with cleaner-burning diesel engines and vehicles, ULSD fuel helps to improve air quality by significantly reducing emissions. As of December 1, 2010, all highway and non-highway diesel fuel offered for sale must be ULSD fuel.

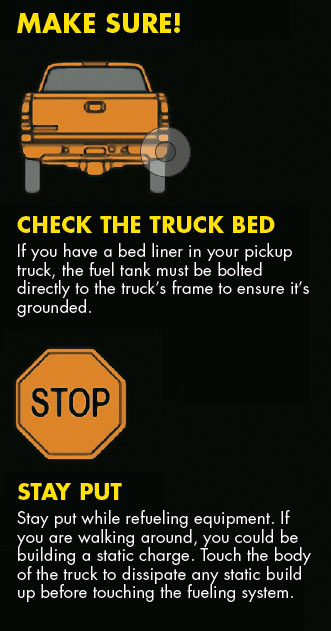

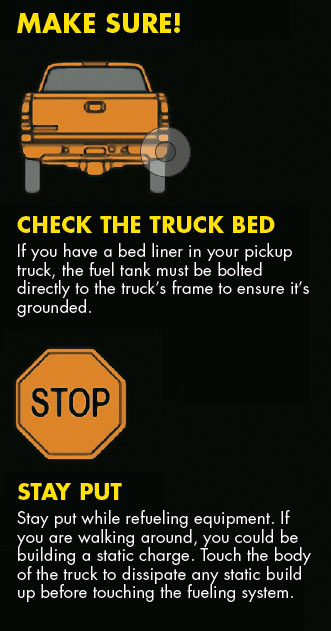

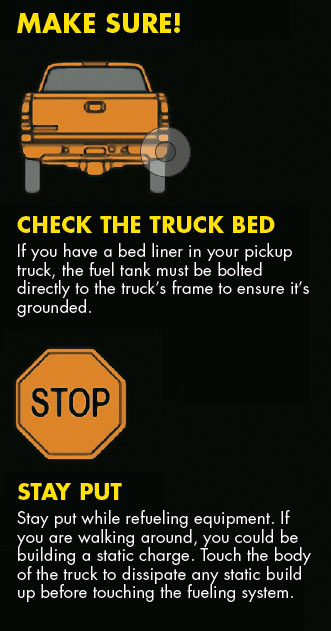

All off-highway diesel-powered machinery (including older legacy construction vehicles) has been using this new formulation of ULSD. While it may not be noticeable to most end-users, there may be a greater risk of static electricity ignition if a custom-remote refueling delivery system is used that may not comply with proper grounding and bonding practices.

All off-highway diesel-powered machinery (including older legacy construction vehicles) has been using this new formulation of ULSD. While it may not be noticeable to most end-users, there may be a greater risk of static electricity ignition if a custom-remote refueling delivery system is used that may not comply with proper grounding and bonding practices.

As a result, contractors should consult with their fuel or fuel system supplier to ensure the delivery system is in compliance with fueling standards for proper grounding and bonding practices.

IMPORTANT CHANGES IN ULSD FUEL FORMULATION

AEM has issued a new bulletin that provides contractors with industry-driven end-user guidance on safely refueling with ULSD.

“ULSD…Not Your Same Old Diesel Fuel Anymore” is AEM’s new best practices guidance bulletin that warns of the greater static electricity ignition hazards associated with use of ULSD.

“About 90 percent of off-road equipment is run on diesel and at one time the fuel had upwards of 5000 ppm sulfur content compared with 15 ppm today,” states Mike Weber, AEM technical and safety services manager. “ULSD is now required for on-highway and off-highway applications in the North American market and we need to educate users who may be unaware of the changes in the physical properties of ULSD and the potential for harm during refueling.”

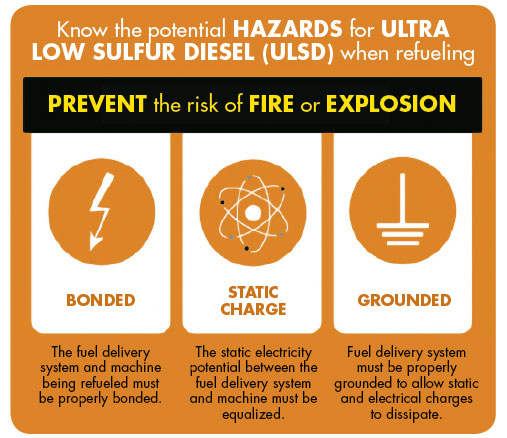

The new bulletin explains that the removal of sulfur and other compounds in ULSD fuel decreases its conductivity and increases its ability to store static charge.

Static charges can build up in ULSD fuel while it is flowing through fuel delivery systems, the bulletin states. Static electricity discharge when combustible vapors are present could result in a fire or explosion.

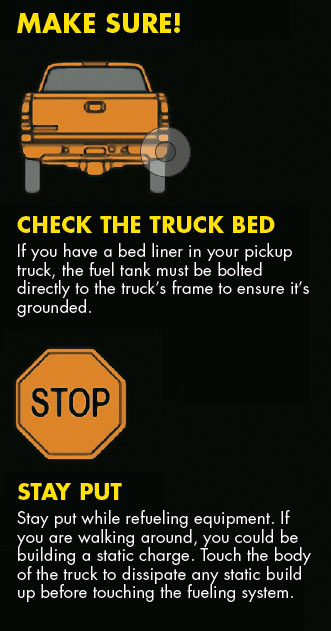

Therefore, it is important to ensure that the entire system used to refuel your machine (fuel supply tank, transfer pump, transfer hose, nozzle, and others) is properly grounded and bonded.

WHAT IS BASIC BONDING AND GROUNDING?

The AEM bulletin states that a properly bonded fuel delivery system has an electrically conductive and unbroken connection between all components of the fuel delivery system, including the fuel supply tank, transfer pump, transfer hose, nozzle, and others.

A properly grounded fuel delivery system has an electrically conductive connection from the fuel delivery system tank to earth ground to allow static and electrical charge dissipation.

“Proper bonding and grounding of fuel delivery systems is important during refueling,” the bulletin states.

ULSD Bulletin Available as a Free Download from AEM

A multi-sector AEM ad hoc committee of member companies developed the best practices bulletin. AEM is encouraging industry groups and government entities to disseminate the bulletin to foster widespread understanding of the related risks during ULSD refueling.

The new bulletin may be downloaded free from the Safety, Regulatory & Technical section of the AEM website at www.aem.org.

[clear]

■ ■ ■

[divider]

For More Information For more information on the ULSD Best Practices Guidance Bulletin, contact AEM’s technical and safety services manager Mike Weber at mweber@aem.org, or call 414.298.4149.

Modern Contractor Solutions, July 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions Magazine!