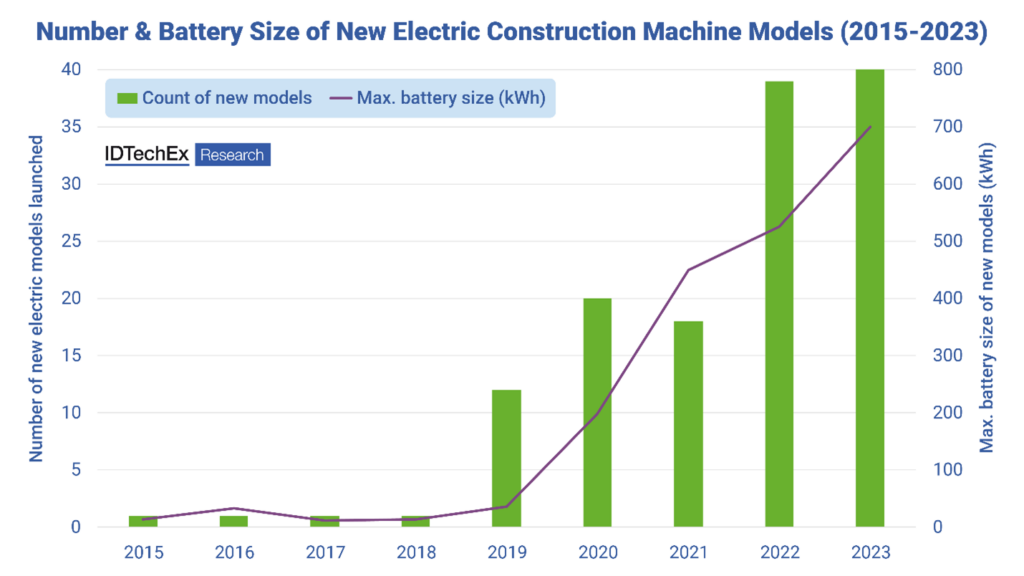

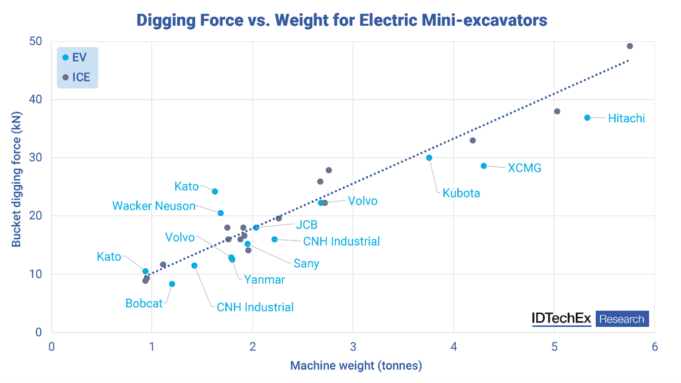

| By Pranav Jaswani, Technology Analyst at IDTechEx The construction machine industry is still in its early stages of electrification, with the first small electric machine only coming onto the market in 2015. However, IDTechEx’s new report, “Electric Vehicles in Construction 2024-2044: Technologies, Players, Forecasts”, highlights how the electric machines of today are bigger and better than their predecessors from less than 10 years ago. OEMs worldwide are picking up the pace of electric machine development, and IDTechEx finds the industry will grow to be worth over US$126 billion in 2044. Machine performance continues to improve The first electric machines to come onto the scene were mini-excavators. Their smaller sizes and less intense workloads made them the ideal testing ground for construction electrification. Many construction companies’ concerns then were whether these electric machines could withstand the demands of the job site and deliver similar performance to diesel engines. IDTechEx’s new report finds that electric mini-excavators are now at a point of development where they can match diesel on virtually all key metrics. EVs offer up equivalent or even superior power to diesel machines, with models from Kato and Wacker Neuson able to generate 30-60 percent more digging force than an average diesel machine of the same size. Significant improvements have been seen in the runtime of these machines too. Where the first machines on the market only achieved 4 to 6 hours of operation on a single charge, newer machines can manage up to 8 hours of operation (a full workday) as standard. Persistent battery development has played a huge part in this increase, and IDTechEx expects runtimes to reach 9 to 10 hours in the near future. Large excavators and loaders are coming to the fore While mini-excavators dominated the early phases of electric construction machine growth and are still the market’s largest segment, the development focus has pivoted onto large excavators and wheel loaders. Together, these two machine types made up 35 percent of all equipment sales in 2023 and are some of the heaviest emitters of greenhouse gases on the job site, contributing to over 50 percent of all construction machine emissions. Their electrification is, therefore, key to furthering the decarbonization of the global construction industry. As the rate of new electric machine models entering production has increased from 2019 to 2023, so has the size of these machines. Where 3-tonne mini-excavators once represented the height of electric machine technology, multiple OEMs now have large excavator models weighing 20 tonnes or greater. The Chinese OEM Know-How even started producing a 52-tonne electric excavator in 2023, which is by far the largest seen to date. Wheel loaders have reached a similar stage, with new 20-tonne machines now being the norm for electrification. Bigger machines necessitate bigger and more advanced battery systems, and the rise of electric excavators and wheel loaders has seen battery sizes in construction shoot up dramatically over the last 5 years. The maximum battery size installed in newly produced models has consistently gone up from ~30 kWh in 2018 – used in mini-excavators and similar compact machines – to over 500 kWh in 2023. The Know-How 52-tonne excavator is equipped with an enormous 700 kWh battery, which IDTechEx estimates would cost US$210,000 on its own and weigh over 3.5 tonnes. What’s next for EV construction machines? Many of the larger machines now entering the market have already gone down the same path as mini-excavators in matching the performance of diesel counterparts. OEMs are at a stage where performance parity is no longer challenging to achieve and are focused on expanding their EV portfolios into bigger machines and new equipment types. Chinese OEMs have been market leaders in this sense, developing larger excavators and wheel loaders while also being proactive in the electrification of mobile cranes weighing in the hundreds of tonnes. Battery advancements will play a huge part in determining the future of the electric construction industry. OEMs currently achieve battery pricing far above what is seen in the automotive market, but increasing the scale of EV production and setting up dedicated supply chains will help bring down costs. At the same time, improving the efficiency of existing battery technologies and bringing in more advanced Li-ion and future battery technologies will widen the types of machines that can be electrified and further enhance their performance. The new IDTechEx report “Electric Vehicles in Construction 2024-2044: Technologies, Players, Forecasts” provides deeper analysis of the future of the electric construction machine industry. It finds that the industry will grow at a CAGR of 21 percent to reach US$126 billion in value by 2044. For more information, visit www.IDTechEx.com/EVConstruction. |