Over the years, screen blinding and pegging have been barriers to efficient material screening that processors have sought to overcome via a variety of half-measure solutions including: frequent washing, slap chains, ball decks, and heated decks. Screen blinding of media is typically a result of fine material accumulating around screen openings—remaining unaffected by a machine’s vibration. Similarly, pegging ensues when an irregular material enters the screen apertures but is unable to pass through.

KLEAR-SCREEN SOLUTION

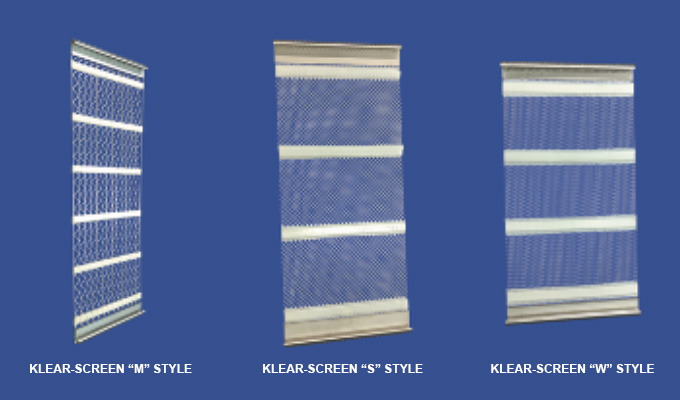

In response to the demand from a vast array of aggregates, minerals, and other media processors, Midwestern Industries, Inc. (Massillon, Ohio), a leading manufacturing mainstay of innovation for the screening industry since 1953, introduces its new KLEAR-SCREEN series panels. The series (Styles: S-M-W) design features spaced wire cloth urethane strips that essentially operate as live moving wires, to create more through-put to dislodge materials. Ultimately, the resulting “near size” particles wont’ blind the screens.

The non-blinding, wire cloth clear screen’s urethane strip designs are spaced across the panels and the wire flexes so it won’t fall apart—meaning less screen changes. Made to fit most applications and rectangular vibrating machines, each series’ panel is available in openings ranging from 1/16-inch to 1-inch and in a variety of wire sizes.

The KLEAR-SCREEN design configuration increases screening efficiency, extends screen life, and produces a consistent product—decreasing costs per ton.

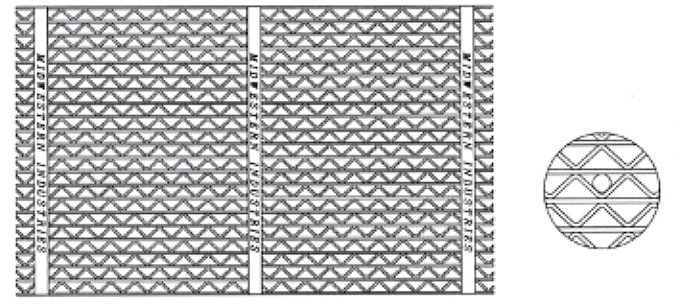

“S” STYLE: Most Common Weave … Square Type, More Precision

Midwestern’s KLEAR-SCREEN “S” style screen panels are ideal for applications with a high percentage of near sized particles that often cause blinding in traditional woven mesh screens. This style of screen has a square opening and is measured the same as woven wire openings.

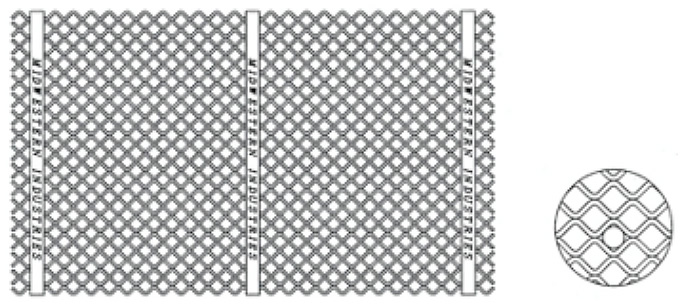

“M” STYLE: High Impact … Precise Sizing

Midwestern’s KLEAR-SCREEN “M” style screen panels are ideal for applications with high impact and heavier loading. This style is also great for smaller openings for fine material. The “M” style screen has a triangle opening which is obtained by alternating crimped and straight wires. The crimped and straight wires vibrate at different frequencies—practically eliminating blinding and optimizes throughput.

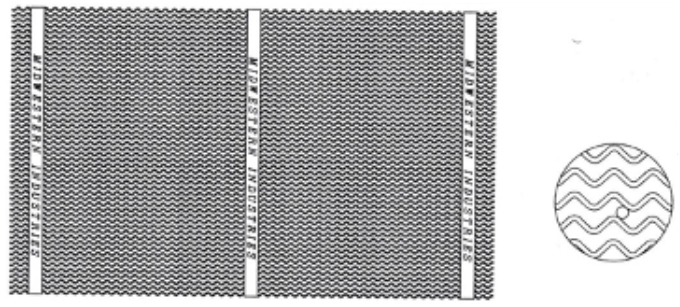

“W” STYLE: More Open Area … High Production

Midwestern’s KLEAR-SCREEN “W” style screen panels are ideal for applications with a high percentage of fine material. The “W’ style screen offers the largest percentage of open area in the KLEAR SCREEN line-up. It utilizes a “W” shaped opening with all wires parallel to each other.

CLOSING THOUGHT

Midwestern’s new KLEAR-SCREEN wire product series premiered to potential end-users in March at the CONEXPO/CONAGG 2020 (Las Vegas, Nevada), and will be available to order in late summer 2020.

According to Midwestern’s president of manufacturing and sales, H.J. “Chip” Painter, “The launch of our KLEAR-SCREEN panel series unique designs overcome the age-old issue of pegging/blinding, which prevents fine material from passing through. Screening efficiency is key … KLEAR SCREEN consistently achieves that goal.”

<for more information>Since 1953, Midwestern Industries, Inc. has been a mainstay of innovation for the screening industry, delivering customized manufacturing and design solutions for a myriad of processing industries including: Pharmaceutical, Food & Beverage, Chemicals, Aggregates, Shot Peening, Plastics, Brick and Clay, Ceramics, and Powdered Metals, amongst others. Known throughout the industry as “The Sizing People®,” Midwestern’s comprehensive product line offers advanced application solutions for handling coarse, fine, wet, and dry materials with the ability to screen and separate particles from 20 microns and up. For more, visit www.midwesternind.com.