Lighting efficiencies highlighted with use of LED technology

By Susan Azevedo

Light-emitting diode (LED) technology is revolutionizing the lighting industry. LED lights don’t waste energy by converting it to heat; they convert energy to light of a single color within the visible spectrum.

But it takes more than just a lightbulb to revolutionize jobsite lighting. Traditional temporary bulb-based string lights and highbays have multiple inefficiencies beyond simply using incandescent bulbs. In addition to wasting energy, traditional lights are associated with high material and labor costs.

LIGHTING THE JOBSITE

A typical jobsite uses a variety of temporary lighting products, many of which are labor-intensive to install and maintain. Often, the lighting may need to be repositioned as the project progresses, which is difficult to do with string lights or tower lights. The bulbs are fragile and need to be replaced quite frequently. A conservative estimate is that, on average, bulbs will either be broken or burn out at least once per year. At this rate of replacement, it is often necessary to maintain a stock of replacement bulbs and assign someone to replace broken or burned-out bulbs throughout the day.

These practical problems impact individual jobsites, but when viewed on a larger scale, there are also systemic problems. Because they are not durable, traditional jobsite lights can rarely be reused on multiple construction projects. Statistics show that less than 20 percent of temporary lighting is recovered and reused on another job. However, since temporary lighting is cheap compared to most jobsite investments—and since consumers tend to assign value based on an item’s price—jobsite lighting has come to be seen as a low quality, disposable product. A race-to-the-bottom cycle has therefore been established. The waste, inefficiency, and duplication associated with traditional lighting has been normalized.

LIGHTING INNOVATION

Lind offers a reinvention of jobsite lighting. The company has 70 years of experience providing dependable portable electrical equipment, giving them a deep understanding of the specific challenges jobsites face. Lind also invests heavily in research and development. The result is a lighting system that is modularized, efficient, and easy-to-use. For example, the Beacon360 Blaze has a pre-installed cord that matches light coverage to OSHA standards. No hardwiring is required because a daisy-chain cable makes installation and removal simple. The recommended spacing for the Beacon360 Blaze is 50 feet apart; therefore, lights come centered on 50-foot cable sections, with a plug at one end and a triple outlet on the other. The lights are customizable and interchangeable.

Fewer LED lights are required to light a jobsite—250 feet of string lights can be replaced with a single LED that provides the same light level (a minimum of 5 foot-candles (FC)). And when installation points are reduced from 25 to one, installation times are 90 percent faster. This translates into substantial labor savings. Furthermore, once they are installed, the cables don’t need to be moved or relocated. With traditional string lights, as walls go up, cords get caught and damaged. Light blockage from ductwork and HVAC installation is another problem with traditional lights. The improved layout of Lind Equipment’s LED Jobsite lights eliminates these problems.

SAVINGS AND SAFETY BENEFITS

Other efficiencies associated with LED lights add up to big savings. Energy consumption is reduced by more than 80 percent, lowering electricity costs. The LED Jobsite community has already saved over 170,000,000 kWh of electricity. The LED Jobsite system is also flexible enough to evolve throughout the project. For example, workers can easily pop the lights onto a tripod for task lighting for finishing or fit-out stages. Purpose-built LED lighting maximizes the directional character of LED lighting, so lighting can be focused where it is needed, and optimal task lighting improves worker productivity.

Jobsite safety is enhanced by using LED Jobsite lighting. Since LED bulbs are cool, workers avoid skin burns. Unlike hot halogen bulbs, which pose a fire hazard when located near flammable materials, LEDs do not pose a fire risk. Furthermore, compact fluorescent and metal-halide bulbs contain mercury and toxic heavy metals; workers can be exposed to these toxins when bulbs break. Fluorescent and metal-halide bulbs also emit UV radiation.

LED Jobsite lights are durable, being IP65 weatherproof-rated and built with polycarbonate and cast aluminum. Durable products translate to a lower total cost of ownership. LED lights can be reused again and again, for years, without any maintenance, becoming a company asset rather than a disposable item.

The savings associated with switching to LED will be exponential over the lifetime of the lights. The benefits compound on a construction site (as opposed to 9-to-5 operations) because lighting is typically run 24 hours a day. The price of LED lights is not as high as many expect, so upfront costs are made up quickly, with the lights completely paying for themselves within months.

VISUAL IMPACT

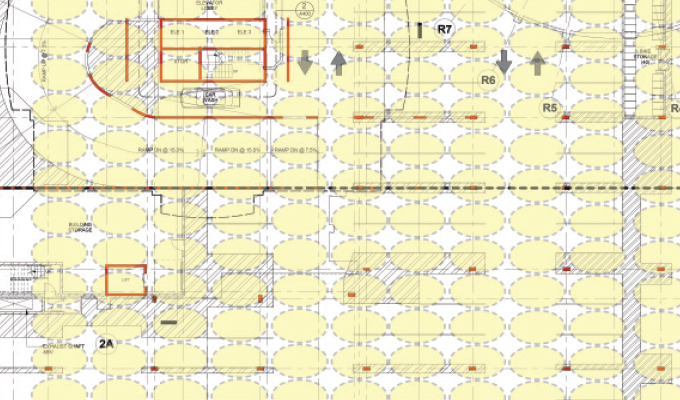

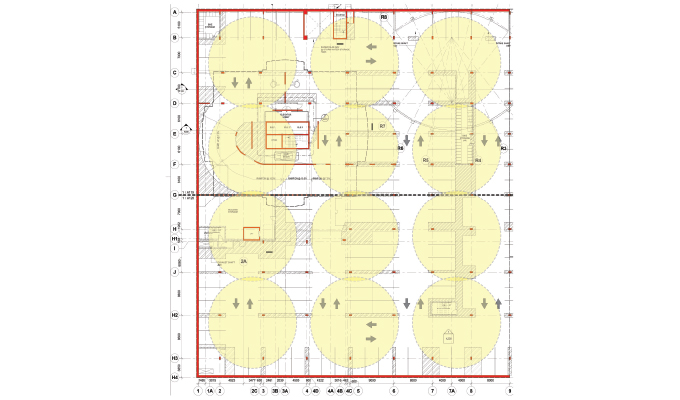

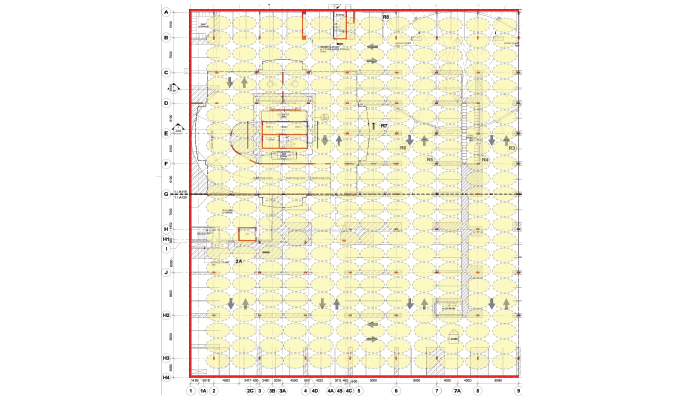

The efficiency gains of LED are visible on the project example shown, a 50,000-square-foot space lit to 5 FC. Image 1 shows a floor plan with the number and layout of string lights required to light the site. Image 2 depicts the number and layout of LED Jobsite lights. Each circle in Image 1 represents 5 FC of light coverage from 28 100-foot sets of bulb-based string lights. Bulbs are 23W compact fluorescent lamp (CFL) or 16W LED bulbs. The layout involves 280 points of installation with 4 x 120V/20A circuits required. Each circle in Image 2 represents 5 FC of light coverage from 12 LED Jobsite Lights (Beacon360 BLAZE). The layout involves only 12 points of installation and the entire area can be run off a single 120V/20A circuit.

CONCLUSION

Construction teams may be used to dealing with hassles when it comes to

About the author:

Susan Azevedo is lead product manager at Lind Equipment, home of The LED Jobsite, Williamsville, New York, and Markham, Ontario, Canada. She can be reached at sazevedo@lindequipment.net or 877.475.5463 x 234. For more than 70 years, Lind Equipment has manufactured portable lighting and electrical equipment for the toughest jobsites.

Modern Contractor Solutions, April 2019

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.