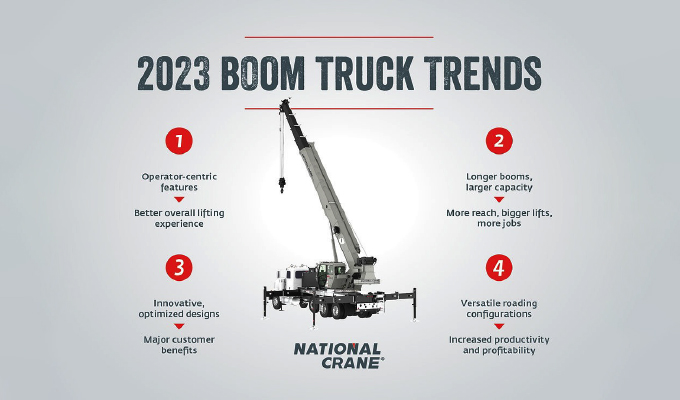

Boom trucks are offering operators increased asset utilization as they steadily muscle in on jobs once reserved for larger cranes. What’s driving this change?

Two decades ago, the gulf between boom trucks and their larger counterparts was clear for all to see. More recently, that distinction has become less obvious—and four leading trends are the chief reasons for such a striking shift.

Boom trucks have now well and truly grown up, even closing the performance gap on their larger siblings. And, according to Bob Ritter, product manager at National Crane—the industry’s leading manufacturer, with over 19 models—that situation looks set to continue.

Operator-Centric Features

“We’re seeing four main trends, with the most general one being the way they’re nibbling into the traditional markets of other cranes,” he says. “There’s been a definite increase in technology and features trickling down from more traditional cranes and being adapted to improve productivity.”

These operator-centric enhancements are perfecting the lifting experience while maintaining the flexibility enabled by a boom truck’s more adaptable design.

Longer Booms, Larger Capacities

One of these enhancements constitutes the second trend—the popularity of longer booms. With extended reach bringing additional jobs onto an operator’s radar, asset utilization is now greatly enhanced from the days when standard boom lengths rarely passed 100 ft.

“Customers want machines that are more versatile and will do more than was historically possible,” Ritter adds. “Our biggest stand-up model offers 127 ft of main boom, and that reaches 151 ft on our swing seats. These longer boom models compete with all players in the market.”

Innovative, Optimized Designs

The same can be said for the third trend. Over the last 15 years, there has been an avalanche of machines launched into the previously untapped 30–60-ton sector. Capitalizing on advances in engineering tools, steel strength, and other materials that have supported increasingly optimized designs, many of those new models were boom trucks. That sector quickly came to constitute the vast majority of their market.

“Once you’re in the 50–60 t range enabled by our NBT50L and NBT60XL, you’re competing with traditional cranes, but often have the advantage of longer reach,” Ritter says. “They’re fine examples of innovative design that optimize the overall package and offer major customer benefits.”

Versatile Roading Configurations

These design improvements are the final trend according to Ritter—or, more accurately, the ease with which a customer can have something special integrated. Whether it’s providing more versatile roading configurations or adding custom complexity to a chassis, National’s Truck Mod Center engineers will work closely with users to understand their precise needs.

“Customers are asking OEMs to be more proactive,” Ritter says. “Our configurations usually allow us to meet most of the state or county roading regulations, sometimes without a permit. But where there is a problem, our design and applications engineers will work with users to make dimensional or weight adjustments to solve it.

“Our boom trucks give us the flexibility to meet our goal of offering the complete package of whatever customers want. We can specify the chassis with them completely, selecting the best suspension, transmission and engine, to maximize the balance between weight and strength.”

The difference between a boom truck and a traditional crane seems to be becoming less and less obvious with every new model introduced to the market.

For More Information

For more information, visit The Manitowoc Company, Inc. at www.manitowoc.com.